Have you ever wondered why 3D printers print diagonally instead of vertically or horizontally? If you’re new to the world of 3D printing, it might seem a bit perplexing. In this blog post, we’ll dive into the reasons behind this printing technique and explore the various factors that influence the printing direction.

From understanding the Z axis and the effects of Z binding to the role of printer belts and the use of supports, we’ll cover it all. Whether you’re curious about printing angles, overhangs, or the anisotropic nature of 3D printed parts, we’ve got you covered. So, grab your coffee and join us on this fascinating exploration of the diagonal world of 3D printing!

Stay tuned for the upcoming sections where we’ll address common questions like printing horizontally, PLA curling, prints shifting, and much more. Let’s dive in and unearth the secrets of why 3D printers choose to print diagonally.

Why Do 3D Printers Print Diagonally

How 3D Printers Found Their Quirky Angle

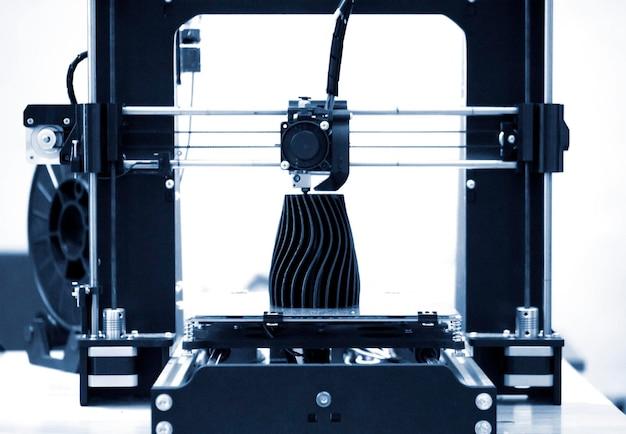

If you’ve ever witnessed a 3D printer at work, you might have been puzzled by the seemingly unconventional diagonal patterns it prints. Why would engineers choose such an unusual approach over the traditional horizontal or vertical methods? Well, fear not, dear reader, for today we shall unravel this mystery with a touch of whimsy and a splash of technical insight.

Printing Diagonally: A Step Toward Efficiency

The Birth of Diagonal Printing

While it may seem like a haphazard choice, the decision to make 3D printers print diagonally actually stems from a keen pursuit of efficiency. Imagine a printer moving along z-axes, layer by delicate layer, to create your desired object. Now, if it were to print in a straight line, it would have to abruptly halt its movement and swiftly reverse direction at the end of each line. Not only would this slow down the process, but it would also lead to inconsistencies in the print.

Optimizing Speed and Structural Integrity

By introducing diagonal printing, engineers discovered a clever way to keep the printer’s momentum flowing smoothly, reducing the need for constant stops and starts. The angled patterns enable the printer to maintain a more continuous motion, drastically increasing efficiency and saving valuable time. Additionally, printing diagonally enhances the structural integrity of the final product. The overlapping layers create a stronger bond between adjacent lines, resulting in a sturdier and more reliable 3D print.

A Dance of Precision and Beauty

A Symmetrical Symphony

Now, let’s talk about the dance of precision that occurs when a 3D printer prints diagonally. Picture this: the printer cautiously moves from one corner of the build area to the opposite one, meticulously laying down filament and creating a symmetrical masterpiece. Just like a skilled artist wielding a brush with elegance, the printer leaves behind a trail of precision and beauty.

The Magic Lies in the Angle

The secret sauce of diagonal printing lies in the carefully calculated angle chosen by the printer. By selecting the perfect diagonal direction, the printer enables each layer to receive optimal support from the previous one, resulting in a structurally sound creation. This dance of angles ensures that the final 3D print maintains its shape, even when facing the challenges of gravity.

In the strange and wonderful world of 3D printing, the choice to print diagonally may appear peculiar at first glance. However, as we have delved into the reasons behind this design choice, we’ve discovered the wisdom and whimsy that lie beneath the surface. So, the next time you witness a 3D printer gracefully creating with diagonal patterns, take a moment to appreciate the efficiency, structural integrity, and beauty it brings to the world of additive manufacturing.

Keywords: 3D printers, print diagonally, efficiency, structural integrity, diagonal printing, optimize speed, symmetrical, precision, dance of angles, additive manufacturing

FAQ: Why Do 3D Printers Print Diagonally

Can You 3D Print Sideways

Yes! 3D printers have the ability to print sideways, thanks to their precise control over the X, Y, and Z axes. This means they can create objects in any orientation you desire, including sideways. So, whether you want to print a unique, eye-catching design or simply need to fit a certain shape into a specific space, sideways printing is definitely possible!

Can You 3D Print an Overhang

Absolutely! 3D printers are capable of printing objects with overhangs, which refers to protruding parts that are not supported from below. This is achieved by utilizing support structures that are generated in the slicing software. These supports act as a scaffold, allowing the printer to successfully print those challenging overhangs. So, whether it’s an intricate statue or a complex architectural model, your 3D printer can handle it!

Can 3D Printers Bridge

Indeed they can! Bridge printing is when a 3D printer creates a horizontal structure between two vertical supports without any additional infill. This requires precise control, as the printer needs to quickly move from one support to the other while maintaining a continuous filament flow. So, go ahead and print those exciting bridge designs with confidence – your 3D printer is up to the task!

What Causes Z Binding

Z binding occurs when the printer’s Z-axis movement becomes obstructed or encounters excessive friction, resulting in irregular or inconsistent layers. This can happen due to various factors, such as misalignment, insufficient lubrication, or mechanical issues. To mitigate Z binding, it’s essential to regularly check and maintain your printer’s hardware, ensuring smooth and unhindered movement along the Z axis.

What Is the Z Axis

The Z axis is one of the three axes of movement in a 3D printer. While the X and Y axes control horizontal movement, the Z axis is responsible for vertical movement, allowing the printer to build layers on top of each other. Think of it as the “up and down” axis that brings your designs to life, layer by layer.

How Tight Should a 3D Printer Belt Be

Ah, the age-old question! Your 3D printer belt should be tight enough to prevent slipping while maintaining smooth movement. Think of it like a guitar string – too loose, and you’ll get a lackluster sound; too tight, and it might snap! A good rule of thumb is to aim for a belt tension that allows you to slightly pluck the belt, producing a taut but not overly strained sound.

What Is Z Hop in Cura

Z hop is a nifty feature found in slicing software like Cura that helps prevent the print nozzle from dragging across previously printed layers when moving between different areas of the model. It achieves this by slightly lifting the nozzle during travel moves, reducing the chances of unwanted collisions and resulting in cleaner, more precise prints.

Is It Better to 3D Print Vertical or Horizontal

Both vertical and horizontal 3D printing have their merits, so it depends on what you’re aiming to achieve. Vertical printing tends to provide better accuracy and surface finish on vertical walls, while horizontal printing is more suitable for printing solid objects with good layer adhesion. Ultimately, it’s up to your design, preferences, and the specific requirements of your project.

Can You 3D Print Without Supports

In many cases, yes! With clever design considerations, it’s often possible to 3D print objects without supports. This can be achieved by incorporating gradual overhangs, chamfers, or utilizing bridging techniques. By strategically angling your design, you can minimize the need for support structures, making the printing process easier and saving time on post-processing.

Can You 3D Print Cylinders

Absolutely! 3D printers are more than capable of creating cylinders of various sizes and dimensions. Whether you need a small pill-shaped container or a large cylindrical vase, your printer can handle it with ease. Just make sure to account for any necessary design details, such as tolerances and wall thickness, to ensure a successful print.

Why Are 3D Printed Parts Anisotropic

Ah, the beauty of 3D printing’s layer-by-layer approach! 3D printed parts can exhibit anisotropic properties, meaning their strength, stiffness, or other mechanical characteristics can vary depending on the direction in which they are tested. This is because each individual layer is bonded together, resulting in different properties parallel or perpendicular to the print layers. Understanding the anisotropic nature of your prints can help you optimize your designs for specific applications.

Why Do Ender 3 Prints Keep Shifting

Oh, those sneaky shifts in your prints! Ender 3 prints can shift for a variety of reasons, including loose belts, misaligned axes, or insufficient cooling for the filament. These shifts can occur when the print head encounters unexpected resistance or when the printer’s mechanics are not properly calibrated. Taking the time to fine-tune your Ender 3’s hardware, ensuring it’s in tip-top shape, can help minimize those frustrating shifts.

What Angle Can a 3D Printer Print

A 3D printer can confidently print at a wide range of angles. However, the optimal angle may vary depending on the specific printer, material, and design. Generally, most printers can handle angles up to 45 degrees without the need for supports. Beyond that, supports may be necessary to maintain the structural integrity and quality of the print.

Why Is My 3D Printer Printing Sideways

If your 3D printer is printing sideways when it should be printing upright, there may be a misconfiguration in your slicing software or an issue with the orientation of your model. Double-check your settings to ensure that the correct orientation is selected, and verify that your model’s design and orientation are suitable for the desired print result. Don’t worry – with a little troubleshooting, you’ll have your printer back to printing things the right way!

Can a 3D Printer Print Horizontally

Absolutely! 3D printers are versatile machines that can print in various orientations, including horizontally. While vertical printing is more common, horizontal printing can be useful for specific projects and designs. Just remember to orient your design correctly in the slicing software for the desired horizontal print, and you’ll be ready to create some unique and captivating prints!

What Causes PLA to Curl

PLA, a popular 3D printing filament, can sometimes curl or warp during printing. Several factors can contribute to this, including improper bed leveling, inadequate bed adhesion, inadequate cooling, or printing at temperatures that are too high. To combat curling, ensure your printer’s bed is properly leveled, consider using adhesion aids like a heated bed or adhesive sprays, and optimize your cooling settings to maintain a stable printing environment.