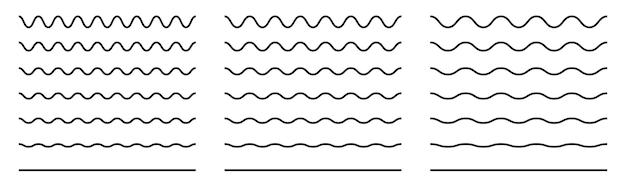

Have you ever wondered why your 3D prints come out with wiggly bottom lines? It can be frustrating when you spend hours designing and printing a model, only to find that the finish isn’t as smooth as you hoped. Don’t worry, you’re not alone! In this blog post, we will explore the common causes behind wiggly bottom lines in 3D prints and discuss the steps you can take to achieve a perfect first layer.

Introduction

When it comes to 3D printing, the quality of the bottom layer is crucial. It serves as the foundation for the entire print, and any imperfections can affect the overall look and structural integrity of the object. So, why is the bottom of your 3D print wiggly? There are several factors that could be at play, from improper bed leveling to incorrect nozzle height. In this blog post, we will dive into the reasons behind wiggly bottom lines and provide you with practical solutions to help you achieve smooth and flawless prints.

So, if you’re tired of wiggly bottom lines ruining your 3D prints, read on! We’ll walk you through the steps to make a perfect first layer, explain how to get rid of “elephant’s feet,” and share tips for smoothing PLA without sanding. Plus, we’ll answer common questions like whether a bad nozzle can cause stringing or if you can smooth PLA with acetone. Get ready to enhance your 3D printing skills and create impeccable prints that will impress everyone!

Why Are the Bottom Lines of My 3D Print Wiggly

What’s Causing the Wobble at the Base

So, you’ve embarked on your 3D printing journey, trying to create magnificent objects out of thin air. But alas, your dreams of perfection are shattered when you find those pesky wiggly lines marring the bottom of your prints. Fear not, for we are here to uncover the mystery and help you defeat this troublesome challenge!

The Shielding vs. Cooling Battle

One possible culprit behind those wobbly bottom lines is the ongoing battle between shielding and cooling. You see, as each layer of your 3D print is laid down, it needs time to cool and harden. Without it, the layers can get all wobbly in the heat. But a necessary evil in 3D printing is the need for a heated print bed or nozzle to ensure proper adhesion. This heated environment sometimes makes it difficult for the layers to cool down effectively, resulting in that unappealing wobble.

Printing in Thin Air? Nope, Not for Your Bottom Lines!

Another sneaky fellow lurking in the shadows is the dreaded lack of support. Imagine building a tower without a solid foundation – it’s just asking for trouble. Similarly, printing objects without proper support structures can lead to wiggly bottom lines. Without a stable base, the layers above have nowhere to rest securely, and the result is a wobbly mess under your freshly printed creation.

The Perils of Speed and Layer Height

Speed can be exhilarating in certain situations, but when it comes to 3D printing, too much speed can lead to disaster. Printing at high speeds might seem like a time-saver, but it can also introduce vibrations that disrupt the delicate balance between layers. These vibrations can manifest as wiggly lines at the bottom, making your prints look less like a masterpiece and more like modern art gone wrong.

Similarly, the layer height you choose plays a significant role. If your layer height is too high, your printer might struggle with precision, resulting in those wobbly foundations. Finding the sweet spot in terms of print speed and layer height can do wonders in your battle against wiggly bottom lines.

Taming the Wild Beast – Solutions and Tips

Now, let’s get down to business and discuss some strategies for taming this wild beast of wiggly bottom lines.

The Magic of Bed Leveling

Having a level print bed is of paramount importance. Just imagine trying to build a wall on an uneven surface – it’s bound to end in crumbles. Take the time to ensure your print bed is leveled properly, making sure it’s neither too low nor too high. This simple step can make a world of difference and help you achieve those clean and crisp bottom lines you desire.

Embrace the Power of Supports

To avoid your prints going all wobbly, supports can be your best friends. Designing or selecting models that include built-in supports can provide the much-needed stability for your object’s bottom layers. These supports can be easily removed later, leaving you with a polished and wobble-free print.

Slow and Steady Wins the Race

While speed may be enticing, slowing things down can actually improve the quality of your prints. By reducing the print speed, you’ll give your layers more time to cool, preventing them from going all wibbly-wobbly. So, take a deep breath, channel your inner Zen, and embrace the slow and steady approach to conquer those wiggly lines.

Fine-Tune the Layer Height

Experimenting with different layer heights can be a game-changer. If you’re facing consistent wobbling issues, trying a smaller layer height might just do the trick. This adjustment allows for finer detail and can greatly minimize those pesky wiggly lines at the base.

Troubleshooting is Half the Battle Won

Remember, my fellow 3D printing enthusiasts, troubleshooting is just part of the journey. Tinkering with settings, experimenting with different speeds and layer heights, and occasionally unleashing a few choice words at your printer are all part of the process. By identifying the causes behind your wiggly bottom lines and implementing the tips we’ve discussed, you’ll be well on your way to achieving those flawless, wobble-free prints in no time. Happy printing, and may the wiggles be forever banished from your creations!

FAQ: Why Are the Bottom Lines of My 3D Print Wiggly

How do I achieve a perfect first layer

Ensuring a perfect first layer is crucial for achieving a flawless 3D print. Here are some tips to help you achieve it:

- Level your bed: Make sure your print bed is properly leveled. An unlevel bed can lead to inconsistencies in the first layer.

- Adjust your nozzle height: Proper nozzle height is essential for a strong first layer. Ensure that your nozzle is neither too close nor too far from the print bed.

- Optimize bed temperature: Different filaments require different bed temperatures. Make sure you set the bed temperature correctly to promote adhesion.

How can I get rid of elephants’ feet

Elephants’ feet, also known as “bottom bulging,” can be quite an annoyance. Here’s what you can do to get rid of them:

- Fine-tune your first layer settings: Adjust the initial layer height and flow rate in your slicer settings until you find the perfect balance.

- Try using a brim: Enabling a brim in your slicer software can provide extra stability to your print’s base, helping to eliminate elephants’ feet.

- Experiment with cooling settings: Cooling your print too quickly or too slowly can cause issues. Adjust the cooling settings in your slicer to find the sweet spot.

Why does the bottom of my 3D print look bad

A poorly-formed bottom layer can ruin the overall appearance of your 3D print. Here are a few factors that may contribute to this issue:

- Improper bed leveling: Make sure your print bed is leveled correctly to prevent uneven base layers.

- Insufficient bottom layer thickness: Adjust the bottom layer thickness in your slicer settings to ensure proper foundation for subsequent layers.

- Excessive print speed: Printing too fast can impact the quality of the bottom layer. Try reducing the print speed to achieve better results.

How can I achieve a smooth surface on PLA prints without sanding

Sanding can be a tedious process. Fortunately, there are alternative methods to achieve a smooth surface on PLA prints without sanding:

- Use a heat gun: Gently heating the surface of your PLA print with a heat gun can help smooth out imperfections.

- Apply a chemical smoothing agent: Some chemical smoothing agents, like ethyl acetate or specific resin mixtures, can dissolve the surface of the PLA slightly, resulting in a smoother finish.

- Post-processing with a flame: Using a small flame, such as from a lighter, carefully pass it over the surface of your PLA print to melt and smooth out any irregularities.

What are the consequences of excessive retraction

While retraction is generally beneficial, excessive retraction can lead to several issues:

- Stringing: Excessive retraction can cause stringing, where thin strands of filament are left behind between different parts of your print.

- Under-extrusion: Too much retraction can lead to under-extrusion, resulting in weak or missing layers in your print.

- Clogging: Excessive retraction can cause filament to retract too far up into the hotend, potentially leading to clogs or blockages.

Can a faulty nozzle cause stringing

Yes, a faulty nozzle can contribute to stringing in your prints. Here’s why:

- Worn-out nozzle: Over time, the nozzle’s diameter can wear down, leading to inconsistencies in filament extrusion.

- Improperly sized nozzle: Using a nozzle with an incorrect diameter in relation to your print settings can cause filament flow irregularities, including stringing.

- Clogged nozzle: A partially clogged nozzle can cause erratic filament flow, resulting in stringing issues.

How do I eliminate visible lines from my 3D prints

Visible layer lines can detract from the overall quality of your 3D prints. Follow these tips to minimize their appearance:

- Adjust layer height: Decrease the layer height in your slicer settings to reduce the visibility of layer lines.

- Increase print resolution: If your printer allows it, choose a higher resolution to enhance the smoothness of your prints.

- Utilize post-processing techniques: Sanding, polishing, or applying a filler primer can help smooth out layer lines and give your prints a more refined appearance.

Can I smooth PLA prints with acetone

Unfortunately, acetone does not work well for smoothing PLA prints. Acetone primarily dissolves ABS plastic and has little effect on PLA. Consider alternative methods like heat treatment or chemical smoothing agents for PLA prints.

Is alcohol effective in dissolving PLA

No, alcohol is not an effective solvent for PLA. PLA is resistant to common alcohols like isopropyl alcohol, making it a safe choice for cleaning or post-processing without worrying about the material dissolving.

Why is my 3D printer printing squiggly lines on the bottom layer

Squiggly lines on the bottom layer can be caused by a few factors:

- Bed leveling: Ensure your print bed is properly leveled to avoid uneven extrusion, which can result in squiggly lines.

- Z-axis inconsistency: Check that the Z-axis movement of your printer is smooth and consistent, as any irregularities can cause wavy lines.

- Extruder issues: A malfunctioning or poorly calibrated extruder can cause inconsistent material flow, leading to squiggly lines on the bottom layer.

How can I achieve a smooth surface on my 3D prints

To achieve a smooth surface on your 3D prints, try these techniques:

- Print orientation: Orient your model so that critical or visible surfaces are printed flat or facing upward.

- Use finer layer heights: Smaller layer heights can lead to smoother surfaces, although it may increase print time.

- Experiment with sanding: If you’re willing to put in some post-processing work, sanding the printed surface can yield significant improvements in smoothness.

What is Z hop and why is it important

Z hop refers to the vertical movement of the print head when it needs to move across printed areas of the model. It helps prevent collision with the printed part, improving print quality and minimizing artifacts caused by nozzle contact.

How can I eliminate visible layer lines on my 3D prints

To eliminate visible layer lines, try the following:

- Optimize print settings: Adjust your printer settings to decrease layer height and increase accuracy, resulting in smoother print layers.

- Post-process with fillers: Applying a filler primer or epoxy resin can help fill in layer lines and create a smoother, polished finish.

- Utilize post-processing techniques: Sanding the printed surface or using various methods like vapor smoothing can greatly reduce the visibility of layer lines.

What should be the bed temperature for PLA prints

For PLA prints, a bed temperature between 50-70°C (122-158°F) is generally recommended. The exact temperature may vary depending on the brand and type of filament, so refer to the manufacturer’s guidelines for optimal results.

Why does the bottom of my 3D print appear stringy

Stringing on the bottom of your 3D print can be caused by a few factors:

- Retraction settings: Insufficient retraction or excessive retraction speed can cause stringing. Experiment with different retraction settings to find the right balance.

- Printing temperature: Printing PLA too hot may lead to increased stringing. Try lowering the printing temperature within the recommended range for your filament.

- Extruder calibration: Poorly calibrated extruders can contribute to inconsistent flow, resulting in stringing. Make sure your extruder steps/mm are accurately set.

How can I achieve a smooth finish on PLA 3D printed objects

To achieve a smooth finish on PLA 3D printed objects, you can try these methods:

- Sanding: Start with a coarse sandpaper and gradually move to finer grits to remove layer lines and smooth the surface.

- Priming and painting: Applying primer and paint can help hide layer lines and give your print a professional, smooth appearance.

- Using a filler: Fillers like epoxy putty or wood filler can be used to fill in gaps and imperfections, giving your print a seamless finish.

Why does filament come out squiggly from the nozzle

Filament coming out squiggly from the nozzle can be caused by the following factors:

- Partial clog: A partial clog in the nozzle can disrupt the smooth flow of filament, causing it to come out unevenly and squiggly.

- Extruder tension: If the extruder tension is too loose or too tight, it can cause filament to be extruded in an irregular manner.

- Z-axis wobble: Any wobbling or inconsistency in the Z-axis movement can result in squiggly filament extrusion. Check for any mechanical issues with your printer.

What causes over-extrusion in 3D printing

Over-extrusion occurs when the printer delivers too much filament, resulting in excess material being deposited. Possible causes of over-extrusion include:

- Incorrect flow rate: Make sure your slicer settings match the actual flow rate of your printer to avoid over-extrusion.

- Improperly calibrated extruder: Calibration issues can lead to inaccurate filament feeding, leading to over-extrusion.

- Incorrect slicing settings: Review your slicing settings for excessive extrusion multiplier or incorrect filament diameter, as they can cause over-extrusion.

What happens if retraction speed is too high

If your retraction speed is set too high, it can lead to several issues:

- Decreased print quality: High retraction speeds can cause excessive stress on the filament, leading to under-extrusion and a decrease in print quality.

- Clogging: Rapid retraction can cause filament to cool and solidify in the hotend, potentially leading to clogs or blockages.

- Increased stringing: Faster retraction can result in increased stringing between printed parts, affecting the overall appearance and accuracy of the print.

Why is my print coming out stringy

Stringing in your print can be caused by various factors:

- Retraction settings: Insufficient retraction distance or speed can cause stringing. Increase your retraction distance or speed to minimize stringing.

- Printing temperature: Printing too hot can cause the filament to be too fluid, resulting in stringing. Lower the printing temperature within the recommended range.

- Filament quality: Some low-quality or older filaments tend to string more than others. Consider using a higher-quality filament to reduce the occurrence of stringing.

How can I remove moisture from PLA filament

To remove moisture from PLA filament, try the following methods:

- Use a filament dryer: Utilize a filament dryer or dry box that maintains a controlled environment to remove moisture from PLA.

- Bake in the oven: Preheat your oven to a low temperature (around 50°C/120°F) and place the filament on a baking sheet for a few hours to remove moisture.

- Desiccant packs: Store your PLA filament with desiccant packs to absorb excess moisture and maintain its dryness.

How do I know if my 3D printer is running too hot

Here are some signs that your 3D printer may be running too hot:

- Stringing: Excessive temperature can cause filament to become overly fluid, resulting in stringing between printed parts.

- Warped prints: If your prints are consistently warping or curling at the edges, it could be an indication of excessive heat during printing.

- Filament discoloration: PLA filament that becomes discolored or turns yellow during printing may be a sign of excessive heat.

Does PLA react with rubbing alcohol

No, PLA does not react with rubbing alcohol. You can safely use rubbing alcohol to clean your PLA prints without any adverse effects on the material.