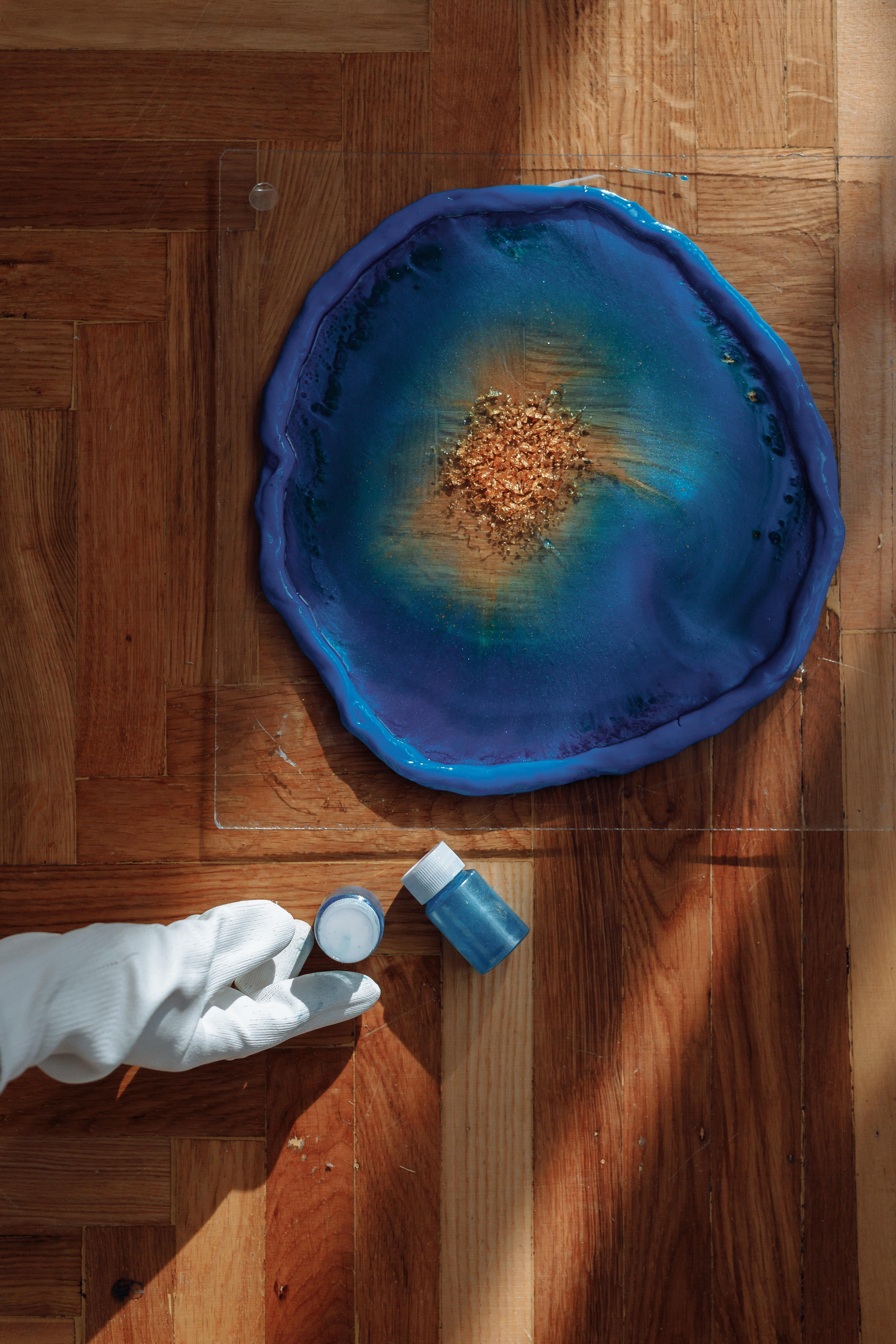

Resin art has gained immense popularity in recent years, captivating artists and crafters alike. If you’ve dabbled in resin projects, you’ve likely encountered the suspenseful waiting period of when to remove your creation from its mold. With so many questions swirling around the topic, it’s time to clear the air and provide some answers.

In this informative blog post, we’ll delve into the world of resin and molds, addressing common concerns such as curing time, resin types, temperature considerations, and more. Whether you’re a seasoned resin artist or just starting out, understanding when and how to safely extract your resin masterpiece from its mold is essential to achieving the desired results.

So, if you’ve ever wondered about the optimal timing for releasing resin from its mold, let’s dive in and explore the factors that come into play.

When Can You Take Resin Out of the Mold

So, you’re all excited about pouring resin into a mold and creating a masterpiece. But hold on a second! You might be wondering, “When can I finally unleash my creation and take the resin out of the mold?” Well, my friend, let me answer that burning question for you.

The Waiting Game Begins

Patience is a virtue, they say, and boy, are they right! After pouring resin into a mold, you need to give it some time to work its magic. Generally, the curing process takes anywhere from 12 to 24 hours. Now, I know that waiting can be as agonizing as watching paint dry, but trust me, this patience will pay off in the end.

Feeling the Heat

Did you know that temperature plays a crucial role in the resin curing process? Yep, just like Goldilocks and her porridge, resin likes it just right. So, make sure you’re conducting this resin-rific experiment in a space with a temperature range between 70 to 80°F (21 to 27°C). Anything too hot or too cold might hinder the curing process, and we definitely don’t want that.

Use Your Fingers… or Not

Now for the moment of truth! Can you take the resin out of the mold? Well, it depends. Some resins have a nifty little trick up their sleeve—they let you know when they’re ready to be released. How? By not sticking to your fingers when you lightly touch the surface. If it feels tacky or sticky, it’s a big fat “no” for removal. But if it’s smooth sailing, go ahead and gently demold that beauty!

The Demolding Dance

Picture this: you’re doing a happy dance because your resin is ready to come out of the mold. But hold your horses, my friend! Before you start celebrating like it’s 1999, give your resin a little extra curing time outside the mold. Why? Well, removing it too soon could lead to warping or deformation. So, exercise some restraint and give it an additional 24 to 48 hours to fully cure. Your masterpiece will thank you for it.

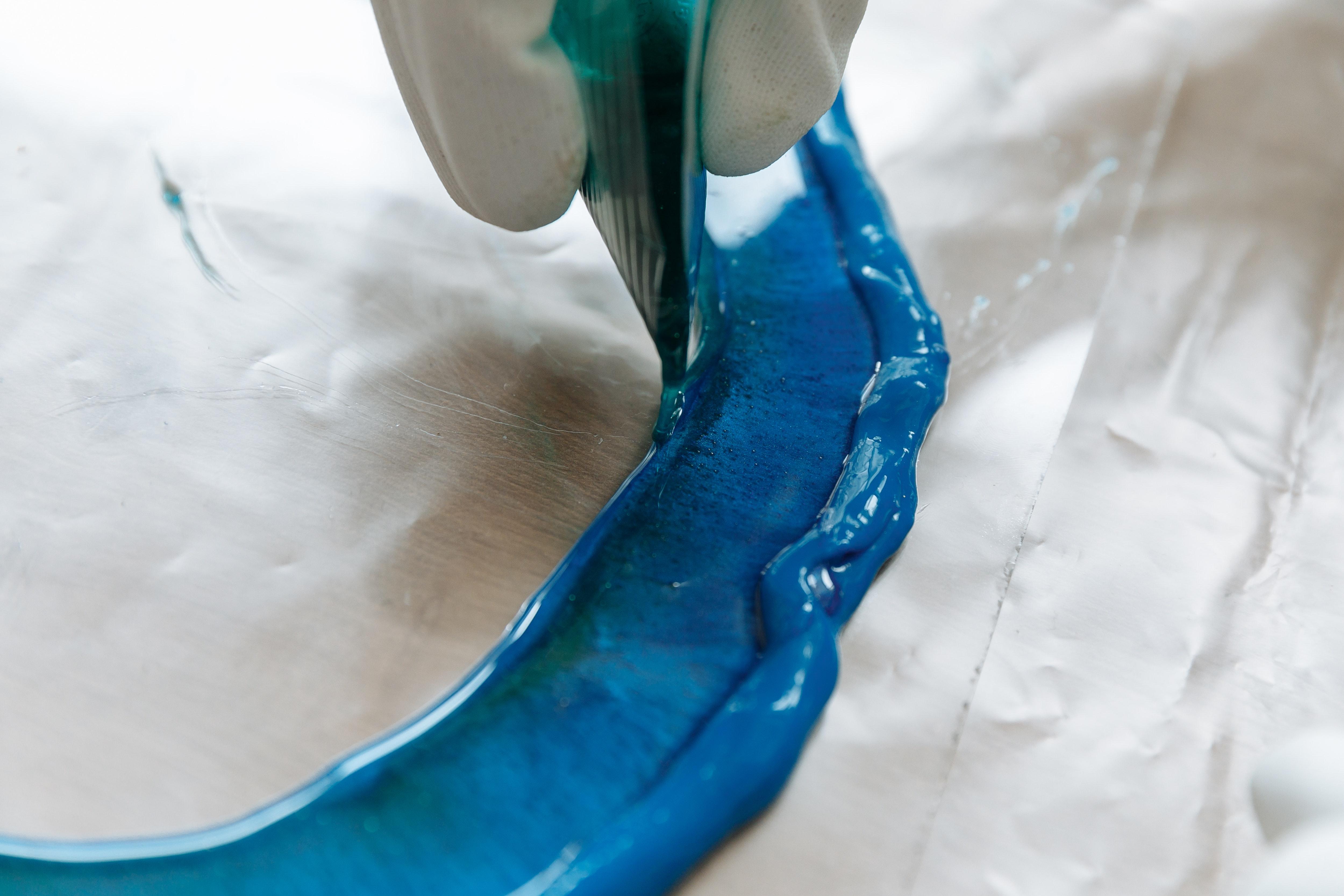

Release the Kraken… I Mean Resin

Alright, the moment has finally arrived! It’s time to release your resin creation from its moldy prison. But here’s a little tip to make things even smoother—a little mold release agent can go a long way. Use a non-stick cooking spray, baby oil, or a fancy-pants commercial release agent to ensure your resin pops right out without a fuss.

Embrace the Imperfections

Remember, my friend, perfection is overrated. Sure, you want your resin creation to look like it was crafted by the resin gods themselves, but sometimes imperfections add character. Embrace the little quirks and blemishes because they make your piece one-of-a-kind. Plus, if someone points out a tiny flaw, you can always say it’s an intentional design choice—own it!

And there you have it, folks! The answer to the ever-burning question: “When can you take resin out of the mold?” Now, go forth, create resin masterpieces, and impress your friends with your newfound resin knowledge. Happy crafting!

FAQ: When Can You Take Resin Out Of Mold

Welcome to our comprehensive FAQ guide on the topic of when you can take resin out of a mold. If you’re a resin enthusiast or a beginner exploring resin art, you’ve probably had questions about the curing process, differences between casting resins and epoxy resins, and more. In this FAQ-style guide, we’ll answer all your burning questions and provide you with the knowledge you need to create beautiful resin crafts with confidence. So let’s dive right in!

When Can You Take ArtResin Out of Mold

Once you’ve poured ArtResin into a mold, it’s important to allow the resin enough time to cure properly before removing it. The curing time depends on factors like the resin brand, ambient temperature, and the thickness of the casting. As a general rule of thumb, most resin brands recommend leaving the resin in the mold for at least 24 to 48 hours. However, it’s always best to check the specific instructions provided by the resin manufacturer to ensure optimal results.

What Is the Difference Between Casting Resin and Epoxy Resin

Casting resin and epoxy resin are both commonly used in resin art, but they have some differences. Casting resin is specifically formulated for casting purposes, such as pouring into molds to create sculptures or jewelry. It has a lower viscosity, which allows it to flow easily into intricate details.

On the other hand, epoxy resin is a versatile resin that can be used for various applications, including coating surfaces and creating artwork. It has a higher viscosity compared to casting resin, making it better suited for projects that require a thick, doming effect or a high-gloss finish. So, while both resins serve different purposes, they can both be used to create stunning resin art.

Why Is My Resin Not Smooth

If you find that your resin surface has imperfections or isn’t as smooth as you’d like, don’t worry, it’s a common issue. There are a few possible reasons for this. It could be due to improper mixing of the resin and hardener, insufficient curing time, or ambient humidity affecting the curing process.

To achieve a smooth finish, ensure you mix the resin and hardener thoroughly according to the manufacturer’s instructions. Additionally, make sure you give the resin enough time to cure completely. If you’re working in a humid environment, consider using a dehumidifier or working in a well-ventilated area to minimize the impact of moisture on the resin’s surface.

How Long Does Resin Last

Resin has a shelf life, and its longevity depends on various factors such as brand, storage conditions, and whether it’s opened or unopened. Generally, most resin brands have a shelf life of around one to two years when unopened. However, once opened, the shelf life can be shorter, typically lasting around six months to a year.

To ensure your resin lasts as long as possible, store it in a cool, dry place away from direct sunlight and extreme temperature fluctuations. If you notice any changes in the resin’s texture or smell, it’s a good indication that it has expired and should not be used.

Do You Need a UV Light to Cure Resin

The curing process for resin can be achieved using different methods, depending on the type of resin you are working with. While some resins require a UV light source to cure, not all resins rely on UV light.

Epoxy resin, for example, cures through a chemical reaction between the resin and hardener. It does not require UV light for curing and will cure on its own over time. On the other hand, certain UV resin brands do require exposure to UV light to initiate the curing process.

Always follow the manufacturer’s instructions for your specific type of resin to ensure it cures properly. If you’re uncertain, reach out to the resin manufacturer for clarification on the appropriate curing method for your resin.

Can You Pour Resin on Rainy Days

Resin is sensitive to moisture, and pouring resin on a rainy day can lead to undesirable results. Moisture in the air can cause the resin to become cloudy, sticky, or fail to cure properly. It’s best to work in a controlled environment with low humidity when working with resin.

If you find yourself needing to pour resin on a rainy day, consider using a dehumidifier in your workspace to reduce moisture levels. Ensure the area is well-ventilated and free from drafts that could introduce additional moisture. Taking these precautions will help you achieve optimal results even when the weather isn’t cooperating.

Does UV Light Cure Epoxy Resin

No, epoxy resin does not require UV light to cure. Epoxy resin cures through a chemical reaction between the resin and hardener. The curing process is initiated when the two components are mixed together, and it progresses over time without the need for additional UV light exposure.

While UV light can be used to enhance certain effects in epoxy resin, such as adding UV-reactive pigments or creating specific designs, it is not a necessary component for the curing process.

Will Epoxy Cure at 65 Degrees

Epoxy resin does cure at lower temperatures, including 65 degrees Fahrenheit. However, curing times may be extended at cooler temperatures. It’s important to note that certain epoxy resin brands have specific temperature guidelines for optimal curing.

Warmer temperatures generally accelerate the curing process, while colder temperatures slow it down. If you’re working with epoxy resin in colder conditions, be prepared to allow for longer curing times to ensure a complete cure.

Will Epoxy Set in Cold Weather

Yes, epoxy resin can set in cold weather. However, low temperatures can significantly slow down the curing process. This means it will take longer for the epoxy resin to fully cure.

If you’re working in cold weather, it’s important to consider the extended curing time and plan your project accordingly. Providing a warm environment, such as using a heat lamp or keeping the resin in a temperature-controlled room, can help maintain optimal curing conditions and shorten the curing time.

Why Is My Resin Bendy After a Week

Resin that remains bendy or flexible after a week has likely not fully cured. There are a few possible reasons for this, such as not mixing the resin and hardener in the correct ratios, insufficient curing time, or using expired resin.

Ensure you’re following the manufacturer’s instructions regarding the resin-to-hardener ratio and mixing thoroughly. Additionally, allow the resin enough time to cure completely, considering factors like temperature and humidity. If you’ve followed the instructions properly and the resin is still bendy, it may be worth reaching out to the resin manufacturer for further assistance.

How Long Does 2-Part Epoxy Resin Take to Cure

The curing time for 2-part epoxy resin varies depending on the brand and specific formulation. As a general guideline, epoxy resin typically cures within 24 to 72 hours. However, it’s important to note that the resin may continue to harden and reach its maximum strength over several days or even weeks.

Always refer to the manufacturer’s instructions for the recommended curing time of your specific epoxy resin. Factors such as temperature, humidity, and the thickness of the resin layer can also affect the curing time.

How Long Do You Leave Epoxy in a Mold

To achieve a proper cure, epoxy resin should be left in the mold for the duration recommended by the resin manufacturer. This duration can vary depending on the resin brand, type of epoxy, and the thickness of the casting.

As a general guideline, most epoxy resin brands suggest leaving the resin in the mold for at least 24 to 48 hours. However, thicker castings or specific epoxy formulations may require additional curing time. Always follow the instructions provided by the resin manufacturer to ensure the best results.

Why Does Resin Take Longer to Cure

The curing time of resin depends on various factors, including the resin brand, ambient temperature, humidity levels, and the thickness of the resin casting.

Thicker resin layers take longer to cure due to the exothermic reaction occurring within the resin. The larger mass of resin generates more heat, which can affect the curing process. Additionally, temperature and humidity play a significant role in curing time. Colder temperatures and higher humidity levels generally slow down the curing process.

Understanding these variables and following the manufacturer’s guidelines for your specific resin will help you determine the appropriate curing time and ensure a successful cure.

How Long Does It Take Resin Art to Dry

The drying time for resin art depends on several factors, such as the resin brand, ambient temperature, humidity levels, and the thickness of the resin layers.

In general, resin art can take anywhere from 24 to 72 hours to dry and cure, but it’s important to note that thicker pieces or multiple layers may require additional curing time. Patience is key when working with resin art, as rushing the drying process may lead to undesirable results.

Consider the drying time as an opportunity to plan your next creative project or catch up on your favorite Netflix series. Remember, good things come to those who wait!

Can I Use a Hair Dryer on Resin

Using a hair dryer to speed up the drying process of resin is not recommended. The heat generated by a hair dryer can cause the resin to cure unevenly, leading to surface imperfections or a tacky finish.

Resin should be allowed to cure naturally at room temperature or within the recommended curing conditions specified by the resin manufacturer. While it may be tempting to expedite the process with a hair dryer, it’s best to exercise patience and give the resin the time it needs to cure properly.

How Long Do You Leave Resin in a Silicone Mold

The length of time you leave resin in a silicone mold depends on the resin brand and the thickness of the casting. Generally, most silicone molds will require at least 24 to 48 hours of curing time, but be sure to consult the guidelines provided by the resin manufacturer for specific instructions.

Thicker castings or certain epoxy resins might require additional curing time. To be on the safe side, leave the resin in the mold for the specified duration and resist the temptation to remove it too early, as this can result in a less-than-desirable finish.

What Is Doming in Resin

Doming in resin refers to the technique of creating a raised, curved, or domed effect on the surface of your resin artwork. This effect is achieved by pouring a thicker layer of resin onto the desired area, causing it to pool and create a raised surface that visually stands out from the surrounding areas.

Doming is often used to emphasize certain elements of a resin piece, add depth and dimension, or create a glossy, reflective finish. So, don’t be shy to give doming a try and take your resin art to the next level!

Do You Need a Heat Gun for Resin

While a heat gun can be useful for certain resin techniques, such as removing air bubbles or manipulating the resin’s surface texture, it’s not a necessity for every resin project.

It’s always good to have a heat gun handy, as it can help resolve small imperfections and give your resin art a professional touch. However, if you don’t have a heat gun or prefer not to use one, you can achieve beautiful results with proper mixing, careful pouring techniques, and patience during the curing process.

Congratulations! You’ve reached the end of our Resin FAQ guide. We hope this comprehensive Q&A-style resource has answered all your burning questions about when to take resin out of a mold. With these insights, you’ll be able to navigate the exciting world of resin art more confidently and create stunning resin projects. Remember to always follow the manufacturer’s instructions and enjoy your resin crafting journey!

Now go forth, embrace your creativity, and let your resin masterpieces shine!