Warehouse automation has revolutionized the way businesses handle their logistics operations. With advancements in technology, the concept of a fully automated warehouse or an automated distribution center is no longer a pipe dream. But how exactly do you automate a warehouse? And what is the price tag attached to such innovations? In this blog post, we’ll delve into the theory, benefits, and costs of warehouse automation, including the expenses involved in implementing automated picking systems. Whether you have a small warehouse or aim for complete automation, we’ll break down the numbers to help you make an informed decision.

Warehouse Automation Cost: How Much Does it Really Add Up

Understanding the Costs Involved

Warehouse automation undoubtedly brings efficiency, accuracy, and cost savings to businesses. However, it’s crucial to have a clear understanding of the costs involved before diving headfirst into implementation. Let’s break down the various factors that contribute to warehouse automation costs:

1. Initial Investment

Any worthwhile venture requires some upfront investment, and warehouse automation is no exception. When considering the cost of automation, it’s crucial to evaluate the initial investment required for equipment, software, and infrastructure. From automated picking and sorting systems to robotics and conveyor belts, these are the physical components that contribute to the initial cost.

2. Customization and Integration

Every warehouse operation is unique, so customization and integration play a significant role in automation costs. Customizing automation solutions to fit specific business needs and integrating them seamlessly into existing systems might require additional expenses. However, this investment can significantly streamline operations and improve overall efficiency in the long run.

3. Maintenance and Upgrades

Like any machinery, automated systems also require maintenance and occasional upgrades. Factoring in ongoing maintenance costs and potential upgrades is essential to ensure the long-term success and reliability of the automation solution.

4. Workforce Transition

Implementing warehouse automation can have an impact on the workforce, necessitating a workforce transition. While automation may reduce the need for manual labor in certain areas, it can also create new job opportunities that require a different and often advanced skill set. Ensuring a smooth transition for employees may involve additional training costs or, if necessary, hiring new staff with relevant expertise.

5. Return on Investment (ROI)

Ultimately, the cost of warehouse automation must be seen in the context of the return on investment it can provide. Automation can lead to significant cost savings by minimizing errors, maximizing throughput, reducing labor costs, and optimizing inventory management. However, calculating the exact return on investment depends on various factors such as the size and complexity of the operation and the specific goals of the business.

While warehouse automation involves upfront costs, it’s essential to consider the long-term benefits it offers to businesses. By streamlining operations, reducing errors, and maximizing efficiency, automation can generate substantial cost savings and improve overall profitability. Understanding and carefully weighing the costs associated with warehouse automation is crucial for making informed decisions and achieving successful implementation. So, by evaluating the initial investment, accounting for customization and integration, factoring in maintenance and upgrades, planning for a smooth workforce transition, and calculating the return on investment, businesses can make well-informed choices that align with their unique needs and goals.

Ready to embrace the future of warehousing? Let’s dive deeper into the world of warehouse automation together!

Fully Automated Warehouse

The Future of Warehousing: Fully Automated

Wouldn’t it be wonderful if warehouses could run on their own, without any human intervention? Well, that dream is slowly becoming a reality with the advent of fully automated warehouses. These futuristic facilities are equipped with cutting-edge technology that allows them to operate efficiently and smoothly.

The Beauty of Automation

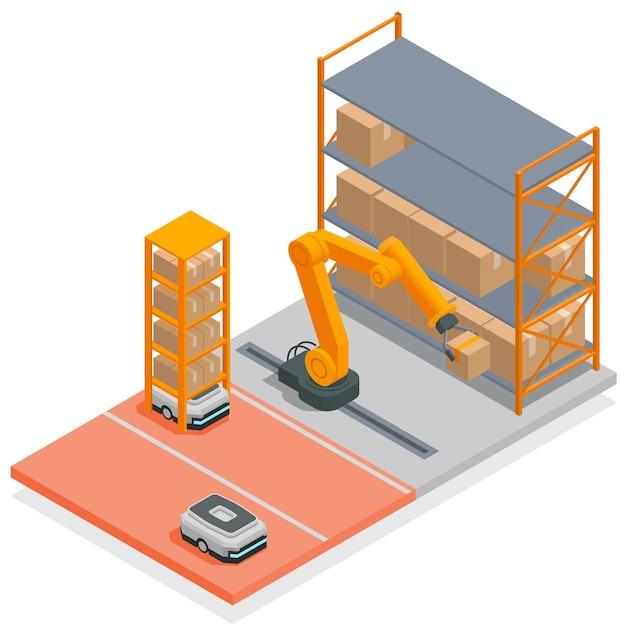

Fully automated warehouses rely on a network of interconnected machines and systems to handle the entire logistics process. From receiving and storing inventory to picking and packing orders, these intelligent systems can do it all.

Streamlined Inventory Management

Gone are the days of manual inventory counts! Thanks to automation, warehouses can now keep track of their inventory in real-time. Smart sensors and RFID technology help monitor stock levels, ensuring that businesses always know what’s in stock and what needs to be replenished.

Efficient Order Fulfillment

No more shuffling through piles of products! With automation, orders can be picked and packed by robotic systems. These robots, equipped with advanced algorithms and sensors, can navigate the warehouse, locate the requested items, and prepare them for shipping. Imagine the time and energy saved with this streamlined process!

Enhanced Operational Accuracy

Automation reduces the risk of human errors, ensuring that every order is accurate and delivered on time. The use of computerized systems eliminates the chances of misplaced items or incorrect shipments, leading to higher customer satisfaction rates.

The Price of Innovation: The Cost of Fully Automated Warehouses

While the benefits of fully automated warehouses are undeniable, it’s important to address the elephant in the room: the cost. Implementing advanced automation technology can be a significant investment for businesses.

Installation and Equipment Expenses

Setting up a fully automated warehouse requires a substantial upfront investment. From purchasing state-of-the-art robotic systems to installing conveyor belts and smart sensors, the initial costs can be steep. However, it’s important to view these expenses as long-term investments that will ultimately result in cost savings and operational efficiency.

Maintenance and Training Costs

As with any high-tech system, regular maintenance and training are necessary to keep a fully automated warehouse running smoothly. Businesses need to allocate resources for equipment upkeep, software updates, and employee training. These periodic costs should be factored into the overall budget when considering the feasibility of automation.

Return on Investment (ROI)

While implementing automation technology might require a significant financial commitment, the long-term benefits can far outweigh the costs. Fully automated warehouses can enhance productivity, reduce labor expenses, minimize errors, and improve overall operational efficiency. When considering the return on investment (ROI), businesses must evaluate the potential cost savings and increased revenue generated by the automated processes.

In conclusion, fully automated warehouses represent the future of the logistics industry. While the initial costs may be daunting, the benefits are substantial. With streamlined inventory management, efficient order fulfillment, and enhanced operational accuracy, businesses can optimize their warehouse operations and provide superior service to their customers. As technology advances and becomes more accessible, the cost of automation is likely to decrease, making it an even more attractive option for businesses looking to stay ahead of the competition.

Small Warehouse Automation

Introduction

In the world of warehouse automation, size doesn’t matter! Even small warehouses can benefit from implementing automation systems. While the focus is often on large-scale operations, small warehouses can achieve significant improvements in efficiency, accuracy, and cost savings through automation. In this section, we’ll explore the advantages of small warehouse automation and address any cost concerns.

Cost-Effective Solutions for Small Warehouses

Streamlined Inventory Management

One of the key benefits of automation in small warehouses is streamlined inventory management. By automating processes such as order fulfillment, picking, and restocking, small warehouses can reduce errors and optimize storage space. With automated systems tracking inventory levels in real-time, small businesses can ensure they have the right products on hand, reducing the risk of stockouts or overstocking.

Improved Order Accuracy

Order accuracy is crucial for any warehouse, regardless of size. Small warehouses can greatly benefit from automation technology that minimizes human error in order fulfillment processes. With barcode scanning, automated sorting systems, and robotics, the chances of shipping the wrong product or quantity decrease significantly. Not only does this improve customer satisfaction, but it also reduces the costs associated with returns and re-shipping.

Efficient Productivity Boost

Automation in small warehouses can revolutionize productivity. By automating repetitive and time-consuming tasks, such as labeling, packaging, and sorting, employees can focus on more strategic and value-added activities. With the help of automated conveyor systems and robotic assistants, small warehouses can handle larger order volumes without the need for additional staff. This boost in productivity allows small businesses to scale their operations and remain competitive in the market.

Scalability and Flexibility

Another advantage of small warehouse automation is its scalability and flexibility. Automation systems can be tailored to the specific needs of small warehouses, ensuring a cost-effective solution without excessive investment. Small businesses can start with basic automation tools and gradually expand their capabilities as they grow. Whether it’s adding more robots or integrating new software, automation offers the scalability and flexibility required to adapt to changing business demands.

Don’t let the size of your warehouse hold you back from embracing automation. Small warehouses can overcome cost concerns by taking advantage of streamlined inventory management, improved order accuracy, productivity boost, and scalability offered by automation solutions. By investing in automation, small businesses can optimize their operations, reduce costs, and stay ahead of the competition in today’s fast-paced business world. So why wait? Start exploring the possibilities of automation for your small warehouse today!

Automated Distribution Center

As industries continue to evolve, businesses are increasingly turning to automated distribution centers to streamline their operations. With technological advancements in robotics and artificial intelligence, companies can now optimize their supply chain management like never before. In this section, we will explore the benefits and cost considerations of implementing an automated distribution center.

Enhanced Efficiency and Accuracy

Automation in distribution centers offers unparalleled efficiency and accuracy in handling various tasks. From receiving and sorting inventory to packaging and shipping, automated systems can perform these operations with remarkable speed and precision. By eliminating manual errors and reducing human intervention, businesses can ensure consistent quality, minimize order processing time, and ultimately enhance customer satisfaction.

Reduced Labor Costs

One of the significant cost-saving factors of implementing automated distribution centers is the reduction in labor expenses. With robots and machines taking over routine tasks, businesses can considerably cut down on manual labor required for picking, sorting, and packaging products. This allows companies to reallocate their workforce to more value-added roles, such as quality control, customer service, and process optimization.

Optimized Space Utilization

Automated distribution centers can optimize space utilization by incorporating efficient storage systems, such as robotic racking and retrieval systems. These systems can make use of vertical space efficiently, maximizing storage capacity without the need for additional warehouse expansion. By utilizing every inch of available space, businesses can reduce their real estate costs and improve operational productivity.

Scalability and Adaptability

Automation provides businesses with the flexibility to scale operations seamlessly as demand fluctuates. Whether it’s increasing or decreasing order volumes, automated systems can be easily adjusted to meet evolving business needs. Additionally, the adaptability of automated distribution centers allows for quick integration with existing warehouse management systems, ensuring a smooth transition without major disruptions.

Advanced Analytics and Insights

Automated distribution centers generate an immense amount of data, which can be utilized to gain valuable insights into operational performance. By leveraging data analytics and machine learning algorithms, businesses can identify areas for improvement, optimize inventory management, predict demand patterns, and make data-driven decisions. These insights contribute to increased efficiency and cost savings in the long run.

Implementing an automated distribution center may require a significant upfront investment. However, the long-term benefits, including enhanced efficiency, reduced labor costs, optimized space utilization, scalability, and access to valuable data insights, make it a worthwhile investment for businesses looking to stay competitive in the rapidly changing marketplace. With the automation revolution well underway, embracing this technology can position businesses for success in the future.

How Do You Automate a Warehouse

Introduction

Automating a warehouse can be a game-changer for businesses, allowing them to streamline operations, increase efficiency, and reduce costs. But how exactly do you go about automating a warehouse? In this section, we’ll explore the steps involved in bringing automation to your warehouse and reaping its many benefits.

Assessing Your Needs

Before diving into warehouse automation, it’s essential to assess your specific needs. Start by analyzing your current processes and identifying areas that could benefit from automation. This could include tasks such as inventory management, order picking, and packing. By understanding your pain points, you can effectively determine the automation solutions that will best suit your warehouse.

Establishing Goals

Once you’ve identified the areas for improvement, it’s time to set goals for your warehouse automation project. Determine what you want to achieve through automation, whether it’s reducing labor costs, increasing throughput, or improving accuracy. Setting clear goals will guide your decision-making process and help you measure the success of your automation efforts.

Researching Automation Technologies

With your goals in place, it’s time to research the various automation technologies available. This could include robotics, conveyor systems, or warehouse management software. Look for solutions that align with your specific needs and budget. Don’t hesitate to reach out to experts in the field or attend trade shows to gain a deeper understanding of the options available to you.

Choosing the Right Solution

Once you’ve done your research, it’s time to choose the automation solution that best fits your warehouse. Consider factors such as cost, scalability, ease of implementation, and compatibility with your existing systems. It’s essential to select a solution that not only addresses your current needs but also has the flexibility to adapt to future changes in your business.

Implementation and Training

After selecting the right automation solution, it’s time to implement it in your warehouse. Work closely with the automation provider to ensure a smooth transition and proper installation. Once the system is in place, provide thorough training to your staff to ensure they understand how to operate and maintain the automated equipment. This will maximize the efficiency and effectiveness of your automated warehouse.

Continuous Improvement

Warehouse automation is not a one-time fix. It’s an ongoing process that requires continuous improvement. Regularly evaluate your automated processes, gather feedback from your team, and identify areas for optimization. Embrace a culture of continuous improvement to ensure your automated warehouse operates at peak performance.

Automating a warehouse may seem like a daunting task, but by following these steps, you can successfully streamline your operations and enjoy the benefits of increased efficiency and reduced costs. Assess your needs, set clear goals, research automation technologies, choose the right solution, implement it effectively, and embrace continuous improvement. With a well-planned approach, your automated warehouse will be a valuable asset to your business. So, what are you waiting for? It’s time to take your warehouse to the next level with automation!

How Much Does Full Automation Cost

Factors that Influence the Cost

When it comes to warehouse automation, cost is a major consideration. The price tag for implementing full automation can vary depending on several factors. Here are some key aspects that influence the overall cost:

1. Warehouse Size and Layout

The size and layout of your warehouse play a significant role in determining the cost of automation. Larger warehouses with complex layouts may require more equipment and customization, which can drive up the expenses. On the other hand, smaller warehouses with simpler layouts may be more cost-effective to automate.

2. Technology and Equipment

The type and complexity of the automation technology and equipment you choose will directly impact the cost. High-end automation systems with advanced features may be more expensive but can provide greater efficiency and productivity gains in the long run. It’s essential to balance your technological needs with your budgetary constraints.

3. Process Complexity

The complexity of your warehouse processes can impact the cost of automation. If your processes involve intricate workflows, multiple handling requirements, or specific industry regulations, the automation system might need customization or additional components, which can increase the overall cost.

4. Scalability and Future Growth

Considering your warehouse’s scalability and future growth is crucial. You want an automation solution that can adapt and expand as your business grows. While it may entail a higher upfront investment, it can help minimize the need for major system upgrades or replacements in the future, ultimately saving you money in the long term.

Understanding the Investment

While warehouse automation can come with a substantial cost, it’s essential to view it as an investment rather than a mere expense. Through increased efficiency, accuracy, and productivity, automation can provide significant long-term benefits, including cost savings and improved customer satisfaction.

Getting Accurate Cost Estimates

To get a precise idea of how much full automation would cost for your warehouse, it’s recommended to consult with reputable automation providers or system integrators. They will evaluate your specific requirements and provide customized cost estimates tailored to your business needs.

While the cost of full automation for a warehouse can vary significantly, considering factors such as warehouse size, technology and equipment, process complexity, and future scalability can help you understand and plan for the investment required. Remember, the expense associated with full automation should be seen as a long-term investment with the potential for substantial benefits in terms of efficiency, accuracy, and overall operational success.

Theory on the Benefits of Warehouse Automation

Warehouse automation has revolutionized the way businesses operate, providing numerous benefits that can greatly impact the efficiency and productivity of a warehouse. In this section, we will explore some of the key theories behind the advantages of implementing warehouse automation.

Boosted Operational Efficiency

Warehouse automation streamlines various processes, elevating operational efficiency to new heights. With automated systems in place, tasks such as inventory management, order fulfillment, and product replenishment are executed with precision and speed. This not only reduces the occurrence of errors but also optimizes the allocation of resources, ultimately leading to a more efficient operation.

Enhanced Inventory Control

Maintaining accurate and up-to-date inventory records is crucial for any warehouse. By implementing automation technologies like barcode scanning and RFID systems, businesses gain better visibility and control over their inventory. Real-time tracking allows for quick identification of stock levels, preventing stockouts or overstocking. With accurate inventory data at their fingertips, warehouse managers can make informed decisions and optimize stock levels to meet customer demands efficiently.

Improved Order Accuracy

Order accuracy is paramount in warehouse operations. With automation, the chances of human error are greatly diminished. Automated systems ensure that the correct products are picked and packed, vastly reducing the likelihood of shipping incorrect items to customers. This reduces returns, improves customer satisfaction, and strengthens brand reputation.

Increased Productivity

By delegating repetitive and time-consuming tasks to automation technologies, warehouse workers can focus on more critical and complex responsibilities. Automation can handle mundane tasks like sorting, labeling, and packaging, allowing employees to concentrate on tasks that require human intuition and problem-solving abilities. The result is increased productivity, as workers can dedicate their skills and expertise towards activities that generate more value for the business.

Enhanced Workplace Safety

Warehouse automation promotes a safer working environment by minimizing the risk of accidents and injuries. Automated systems can handle heavy lifting and repetitive movements, reducing the physical strain on employees. Additionally, automation allows for the implementation of safety measures such as automated guided vehicles (AGVs) and safety sensors, ensuring a secure workspace for warehouse personnel.

The theories on the benefits of warehouse automation suggest that implementing automation technologies can significantly improve operational efficiency, enhance inventory control, increase order accuracy, boost productivity, and create a safer working environment. By embracing automation, businesses can position themselves to thrive in an increasingly competitive and fast-paced industry.

How Much Do Automated Picking Systems Cost

Automated picking systems are a game-changer for warehouse efficiency and productivity. But let’s get real for a moment: the question on everyone’s mind is, “How much will it cost me?” Well, fear not, my friend! In this subsection, we’ll dive into the nitty-gritty of automated picking systems’ cost, so you can plan your budget accordingly.

The Price Tag: Let’s Unveil the Mystery

Now, it’s time to reveal the numbers you’ve been waiting for! Brace yourself, because the cost of automated picking systems can vary widely depending on several factors.

1. System Complexity

The complexity of the system plays a significant role in determining the cost. Basic automated systems that handle routine tasks, such as picking and packing, tend to be more affordable. On the other hand, if you have specific requirements, like handling fragile items or working in extreme temperatures, you might need a more sophisticated system – which often comes with a higher price tag.

2. Warehouse Size

Size matters when it comes to automated picking systems. A smaller warehouse with fewer shelving units and inventory will naturally require a less elaborate system. Conversely, if you’re running a colossal distribution center with a gazillion products, expect the cost to climb accordingly. Think about it; it’s like buying a regular-sized pizza versus buying one the size of a small car. The bigger, the pricier!

3. Customization and Integration

Sometimes, an off-the-shelf automated picking system won’t cut it. If you have unique workflows and processes, you might need customization or integration with your existing warehouse management system. While this can add extra digits to the cost, it’s worth it if it optimizes your entire operation.

Let’s Talk Numbers: Budget Considerations

I know, I know – you want concrete figures. While I can’t give you an exact price for your specific situation, ballpark figures are certainly within reach. On average, a basic automated picking system can start at around $50,000 and go up to $500,000 or more for a more complex, fully integrated solution. Remember, though, these numbers are just an estimate, and the final cost will depend on your unique requirements.

The ROI Perspective: It’s All About Savings

Now, you might be thinking, “Yikes, that’s a hefty investment!” But fear not, intrepid reader – let’s consider the return on investment (ROI). While automated picking systems can have a significant upfront cost, they can also deliver substantial long-term savings. Think of it as a wise investment that pays off in the long run, like buying Bitcoin when it was just a couple of cents!

When it comes to investing in warehouse automation, understanding the cost of automated picking systems is crucial. Factors like system complexity, warehouse size, customization, and integration all contribute to the overall cost. While the initial price may seem daunting, the potential for increased efficiency, productivity, and long-term savings make automated picking systems a worthy investment. So, go forth and unleash the power of automation upon your warehouse! It’s time to kick some picking butt!

What is Warehouse Automation

Warehouse automation refers to the use of advanced technology and machinery to streamline and optimize various processes within a warehouse, such as inventory management, order fulfillment, and logistics. By replacing manual labor with automated systems, warehouses can increase efficiency, reduce errors, and ultimately improve overall productivity.

Benefits of an Automated Warehouse

Increased Efficiency and Productivity

One of the key benefits of warehouse automation is the significant boost in efficiency and productivity it offers. Automated systems can perform tasks at a much faster pace than humans, minimizing the time required for various operations. With the ability to handle repetitive tasks without fatigue, automated machines can operate 24/7, leading to increased output and faster order fulfillment.

Enhanced Accuracy and Reduced Errors

Manual processes are prone to errors, such as miscounted inventory or incorrect order shipments. Warehouse automation eliminates these potential mistakes by introducing precise and reliable systems. By utilizing barcode scanners, RFID technology, and automated software, the chances of human error are greatly reduced, resulting in accurate inventory tracking and order processing.

Optimal Space Utilization

Warehouses often face the challenge of limited space. With an automated warehouse system, businesses can make the most of their available space. Automated machines can utilize vertical space efficiently through the use of high-rise storage systems, such as stacker cranes, and automated guided vehicles (AGVs) that can navigate narrow aisles. This maximizes storage capacity and enables better organization of inventory.

Improved Safety

Warehouse automation promotes a safer working environment. By minimizing manual labor, employees are less exposed to potential hazards and the risk of injuries decreases significantly. Automated systems can handle heavy lifting, reducing the physical strain on workers. Moreover, advanced safety features such as sensors and emergency stop mechanisms ensure a secure working environment for both employees and the equipment itself.

Cost Savings

While the initial investment in warehouse automation may seem substantial, it often leads to long-term cost savings. Automated systems increase operational efficiency, reducing labor costs in the long run. Moreover, accurate inventory management helps avoid excess stock, minimizing storage costs. Additionally, the improved speed and accuracy of order fulfillment can lead to customer satisfaction, encouraging repeat business and increasing revenue.

In conclusion, warehouse automation offers numerous benefits for businesses looking to optimize their operations. Increased efficiency, enhanced accuracy, optimal space utilization, improved safety, and cost savings are just some of the advantages that make investing in warehouse automation a wise choice for companies of all sizes.