In the world of engineering and material science, strength is a crucial factor to consider when designing and analyzing structures. Two important terms frequently used in this context are tensile strength and compressive strength. While they may sound similar, they actually refer to completely different properties of materials. In simple terms, tensile strength measures a material’s ability to withstand pulling or stretching forces, while compressive strength gauges its resistance to crushing or squeezing forces.

In this comprehensive blog post, we will delve into the nuances of tensile and compressive strength, exploring how they are measured, their significance in different applications, and why compressive strength is often higher than tensile strength. Whether you are an engineer, a material science enthusiast, or simply curious about the forces that shape the world around us, this article will provide you with valuable insights. So let’s dive in and unravel the secrets of tensile and compressive strength!

What Is the Difference Between Tensile Strength and Compressive Strength

Unraveling the Mystery of Strength

When it comes to strength, there are two titans in the material science arena: tensile strength and compressive strength. These two terms might sound like characters from a superhero movie, but trust me, they play a crucial role in understanding how materials behave under pressure. So, let’s dive deep into the world of material properties and uncover the difference between these two formidable forces.

Tensile Strength: Playing Tug-of-War

Think of tensile strength as a tug-of-war between the molecules within a material. When a force is applied to a material, whether it’s pulling, stretching, or yanking, tensile strength measures the material’s ability to withstand that force without breaking. It’s like testing the limits of a bungee cord before it snaps, sending you plummeting into an abyss of… okay, maybe not that dramatic, but you get the picture.

Compressive Strength: Crush It!

Compressive strength, on the other hand, is like watching a material face a Hulk-like squeeze. When force is applied from opposite directions, squishing, compressing, or crushing the material, compressive strength comes into play. Imagine a superhero trying to crush a car with their bare hands. Compressive strength measures the material’s ability to resist that kind of force without crumbling like a cookie.

Comparing Apples and Oranges

Now that we have a basic understanding of both tensile strength and compressive strength, you might be wondering, are they completely different or just two sides of the same coin? Well, my friend, while they may seem like polar opposites, they actually work hand in hand to define a material’s overall strength.

It’s All about Direction

The key distinction between tensile strength and compressive strength lies in the direction of the force being applied. Tensile strength examines the material’s resistance to forces that pull it apart, while compressive strength focuses on its resistance to being crushed or compacted. It’s like trying to open a jar of pickles versus squishing a bug—you need different strategies for each task.

Strength in Numbers

Both tensile strength and compressive strength are quantified with numerical values, usually expressed in units of pressure, such as pounds per square inch (PSI) or megapascals (MPa). These measurements give us a tangible way to compare different materials and assess their capabilities.

The Plot Thickens: Young’s Modulus

Before we wrap up our exploration of strength, there’s one more important player to introduce: Young’s modulus. This modulus, also known as the elastic modulus or the modulus of elasticity, measures a material’s stiffness or flexibility. It helps us understand how a material responds to stress, whether it deforms easily or holds its shape. Think of it as the material’s personality—whether it’s pliable like playdough or rigid like a steel beam.

In Summary: The Dynamic Duo

In the realm of materials, tensile strength and compressive strength are like Batman and Robin, both essential for a well-rounded understanding of how materials perform under different conditions. Tensile strength tackles the pulling and stretching forces, while compressive strength faces the crushing and compacting forces head-on. Together with Young’s modulus, they form a dynamic trio that unveils the hidden secrets of material behavior.

So, next time someone asks you about tensile strength and compressive strength, you can impress them with your newfound knowledge and maybe even throw in a few superhero references to show off your sense of humor. Stay strong, my friends!

FAQ: What Is The Difference Between Tensile Strength and Compressive Strength

In the world of materials and engineering, two important properties we often hear about are tensile strength and compressive strength. While they may sound similar, they refer to different forces and behaviors. Understanding their differences can help us grasp the unique characteristics and applications of various materials. So, let’s dive into this FAQ-style guide to clarify any confusion and shed some light on the subject!

What is Tensile Strength with Examples

Tensile strength refers to the ability of a material to withstand pulling or stretching forces without breaking. Essentially, it measures the maximum tension a material can handle without deformation or failure. To put it in simpler terms, imagine pulling on a rubber band. The tensile strength of the rubber band determines how far you can stretch it before it snaps.

What is an Example of Compression

On the flip side, compression involves pushing or squeezing a material together. When a material experiences compressive forces, it tends to resist deformation and holds its shape. An example of compression can be observed when you stack books on top of each other. The lower books withstand the weight from above without collapsing, thanks to their compressive strength.

Which Material Has the Highest Tensile Strength

When it comes to the material with the highest tensile strength, the answer lies in something quite unexpected: spider silk. Surpassing even the strongest steel, spider silk exhibits remarkable tensile strength. Pound for pound, it is stronger than steel and tougher than Kevlar. So, the next time you spot a spider web, remember the incredible strength it holds.

Is Tensile Stress a Normal Stress

Yes, tensile stress is indeed a type of normal stress. Normal stress acts perpendicular to the surface of the material, stretching or compressing it. Tensile stress specifically acts to stretch or lengthen the material along with the force being applied.

Is Tensile a Strength

While “tensile” refers to a type of stress or force, it is not a standalone measure of strength. Instead, it quantifies the force experienced by a material when stretched or pulled. To determine the strength of a material under tensile stress, we use its tensile strength.

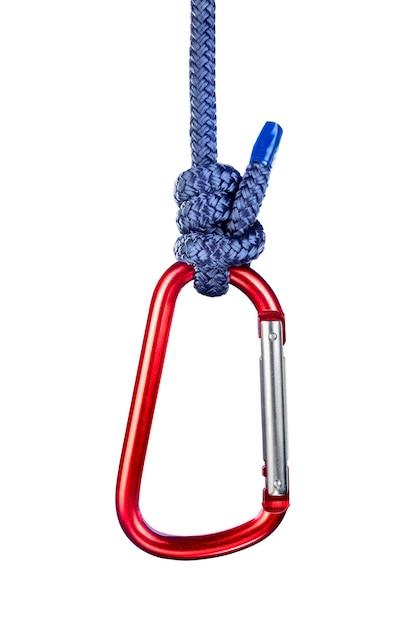

What are Examples of Tensile Forces

Tensile forces manifest in various situations we encounter in everyday life. Think about pulling a door open, stretching a rubber band, or even hanging a heavy object by a rope. These actions all involve the application of tensile forces.

What are the Five Strongest Metals

Curious about the toughest metal out there? Here are five remarkable contenders:

1. Tungsten: Known for its exceptional hardness and high tensile strength, tungsten is widely used in various industrial applications.

2. Steel: Boasting incredible strength, steel alloys have become indispensable in infrastructure, automotive, and manufacturing industries.

3. Titanium: Renowned for its strength-to-weight ratio, titanium finds its place in aerospace engineering and medical implants.

4. Chromium: This shiny metal is celebrated for its excellent corrosion resistance and tensile strength.

5. Iron: With its widespread commercial use, iron alloys possess impressive strength and durability.

What are the Differences Between Tension and Compression

Both tension and compression involve forces acting upon a material, but they have opposite effects. Tension pulls or stretches materials apart, while compression pushes or squeezes them together. Picture a tug-of-war game versus a group of people huddled closely together; that’s the fundamental difference between tension and compression.

How do You Convert Tensile Strength to Compressive Strength

Converting tensile strength to compressive strength requires a bit more than a simple equation. Tensile and compressive strengths tend to be distinct properties that cannot be directly converted from one another. They depend on different atomic structures and material behaviors under different forces. Therefore, it is generally not possible to convert tensile strength to compressive strength, or vice versa.

What is Modulus Strength

Modulus strength, also known as elastic modulus or Young’s modulus, signifies a material’s ability to deform elastically under stress. It quantifies the ratio of stress to strain within the elastic limit. Essentially, it measures how much a material can deform and still return to its original shape once the stress is removed.

What is the Formula for Strength

The formula for strength can vary depending on the specific type of strength being measured. Tensile strength, for instance, is typically calculated by dividing the maximum force applied to a material by its cross-sectional area. On the other hand, compressive strength is determined by dividing the maximum compressive force the material can endure by its cross-sectional area.

What is Material Tension

Material tension refers to the internal forces within a material that arise when it is subjected to stretching or pulling forces. These internal forces counteract the applied tensile forces, helping the material resist deformation or failure.

What is Tensile and Compressive Stress

Tensile stress occurs when a material experiences pulling or stretching forces. Conversely, compressive stress happens when a material is subjected to squeezing or pushing forces. Both types of stress are crucial in understanding how materials behave under different circumstances.

Why is Compressive Strength Higher Than Tensile Strength

The higher compressive strength compared to tensile strength can be attributed to the atomic and molecular structures of different materials. Many materials have stronger internal bonds that allow them to resist compressive forces more effectively. On the other hand, tensile forces can lead to the separation of atoms or molecules, making it easier for materials to break under tension.

What is the Strongest Material on Earth

With its exceptional strength and resilience, graphene claims the title for the strongest material known to humanity. Made from a single layer of carbon atoms, this revolutionary substance exhibits remarkable electrical conductivity, flexibility, and tensile strength. It holds immense potential in fields ranging from electronics to energy storage.

Is Tension Positive or Negative

In engineering and mechanics, tension is typically considered as a positive value. When calculating forces, positive sign convention is often used to indicate tension. However, it’s important to note that tension, as a force, can exist in both positive and negative directions, depending on the context it is being discussed in.

What is the Formula of Tensile Stress

The formula for tensile stress is quite straightforward. It is calculated by dividing the force applied to a material by its cross-sectional area. Tensile stress = Force (F) / Cross-sectional area (A). By evaluating tensile stress, we can gain insight into how materials respond to stretching forces.

What are the Five Mechanical Stresses

Understanding different types of stress is essential in material science and engineering. Here are the five primary mechanical stresses:

1. Tensile Stress: Forces acting to elongate or stretch a material.

2. Compressive Stress: Forces working to squeeze or compact a material.

3. Shear Stress: Forces that cause one layer of a material to slide against another.

4. Torsional Stress: Rotational forces applied to a material, resulting in twisting.

5. Bending Stress: Forces that cause a material to bend or deform in response to an applied load.

Is Higher Tensile Strength Better

Generally, higher tensile strength is desirable as it indicates a greater resistance to stretching or breaking under tension. However, the ideal strength requirement depends on specific applications and factors such as material cost, weight, and design. Finding the right balance between strength and other characteristics is crucial to engineering robust and efficient structures.

Why is Compressive Strength Important

Compressive strength holds great relevance in several real-world scenarios. For instance, it determines the load-bearing capabilities of concrete columns and structural beams. Understanding the compressive strength of a material allows engineers to design buildings, bridges, and infrastructure that can withstand the forces pressing down on them, ensuring the safety of the structures and the people using them.

What is the Difference Between Tensile Stress and Compressive Stress

Tensile stress and compressive stress differ in their effects on materials. Tensile stress stretches or lengthens a material, while compressive stress squeezes or shortens it. They are essentially opposite forces and can have significantly different impacts on the behavior and structural integrity of materials.

And there you have it! By exploring the frequently asked questions about tensile strength and compressive strength, we’ve gained a clearer understanding of these crucial material properties. Keep in mind that while tensile strength measures a material’s resistance to stretching forces, compressive strength determines its ability to withstand squeezing or pressing forces. This knowledge helps engineers and scientists select the right materials for various applications, ensuring the durability and safety of our built environments.