Resin 3D printing has revolutionized the world of additive manufacturing, offering the ability to create intricate and detailed objects with incredible precision. But how strong are these resin 3D prints? Can they withstand the test of time and everyday wear and tear? In this comprehensive blog post, we will explore the strength and durability of resin 3D prints, answering all your burning questions.

From understanding the toughness of different resin materials to comparing the strength of resin prints with other popular printing materials like PLA, we’ll delve deep into the world of resin printing. Additionally, we’ll address common concerns such as print shrinkage, the longevity of resin prints, and the safety aspects of working with 3D resin. So, if you’re curious to learn more about the strength of resin 3D prints and want to discover the toughest resin on the market, you’ve come to the right place. Let’s dive in!

How Strong Are Resin 3D Prints

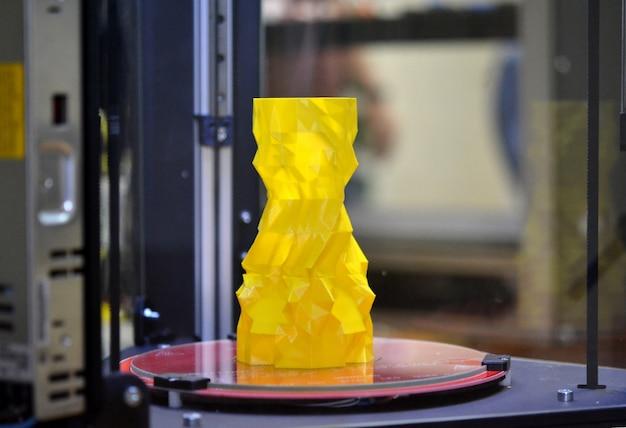

Unleashing the Power of Resin 3D Printing

If you’ve ever wondered about the strength of resin 3D prints, buckle up because we’re about to dive deep into this fascinating world. Resin 3D printing has gained significant popularity in recent years, and it’s time to uncover just how strong these prints can be. Prepare yourself for an eye-opening journey that will leave you in awe of the power of this technology.

The Mythbusters of 3D Printing

Setting the Record Straight on Resin Strength

You might have heard whispers and rumors suggesting that resin 3D prints are as fragile as a snowflake, but let me tell you, those tales couldn’t be farther from the truth. Resin prints are much stronger than you might think, and I’m here to bust those myths wide open.

The Power of Resin Materials

When it comes to resin 3D printing materials, there are various choices available, each with its unique properties and strengths. From standard resins to engineering-grade resins, the strength and durability can vary significantly. It’s like picking a superhero for your specific needs – some are strong like The Hulk, while others are agile like Spider-Man.

Putting Resin Prints to the Test

To truly understand the strength of resin 3D prints, we need to indulge in a series of tests. From drop tests to impact tests, these prints go through it all, just like a cupcake in the hands of a hungry three-year-old. Hold on tight as we explore the astonishing results that will leave you questioning everything you thought you knew about resin prints.

Breaking It Down: Resin Strength in Real-world Situations

Resin in the Face of Mechanical Stress

Whether it’s a functional prototype or a detailed figurine, resilience to mechanical stress is crucial. Picture a resin 3D print facing the challenges of everyday life like a fearless warrior. From withstanding pressure and tension to flexing its muscles under loads, these prints are ready to take on the mechanical world like a champion.

Flexibility and Resilience

Strength is not just about being strong like an elephant; it’s also about being flexible like a majestic gymnast. Resin prints showcase their incredible flexibility, allowing them to bend like a contortionist without breaking. So, go ahead and twist, turn, and bend your resin creations to your heart’s desire – they can handle it.

Conquering Temperature Extremes

Let’s talk about the power of thermal resistance in resin 3D prints. These prints can endure extreme temperatures, ranging from freezing winters to scorching summers. Just like an Olympic athlete pushing their limits, resin prints won’t sweat under the heat, nor will they let the cold freeze their spirit.

The Final Verdict: Myth Busted

A Strong Case for Resin 3D Prints

Prepare to have your mind blown as we unveil the truth about the strength of resin 3D prints. From mechanical stress to flexibility and temperature extremes, resin prints have proved their mettle time and time again. It’s safe to say that when it comes to strength, resin 3D prints are no pushovers – they are the champions of the 3D printing world!

Now that we’ve unraveled the mystery of resin strength, it’s time to unleash your creativity with the knowledge that your resin prints can handle the challenges that lie ahead. So, go forth, my fellow print enthusiasts, and let your imagination run wild with the confidence that resin 3D prints are as strong as Iron Man’s suit!

Stay tuned for more mind-blowing revelations in the world of 3D printing! Don’t miss out on our next adventure, where we’ll explore the extraordinary details hidden within resin prints.

FAQ: How Strong Are Resin 3D Prints

What is the toughest 3D resin

The toughest 3D resin on the market in 2023 is “Super Tough Resin.” This resin is specially formulated to create durable prints with high impact resistance. It’s perfect for functional prototypes or objects that need to withstand heavy use and potential rough handling. With Super Tough Resin, you can sleep soundly knowing your 3D prints are tough as nails!

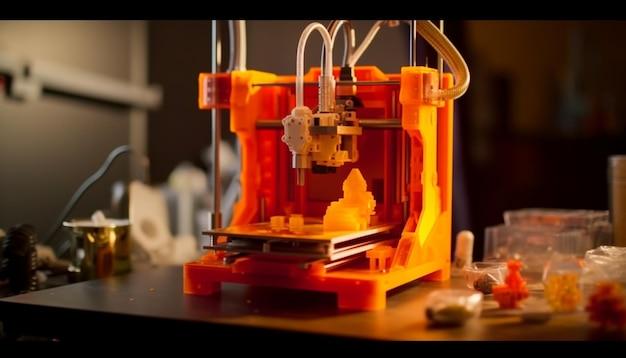

How fast is a resin 3D printer

Resin 3D printers have come a long way in terms of speed, like a cheetah on rollerblades! The speed of a resin 3D printer depends on various factors, such as layer thickness and the complexity of the model being printed. On average, a resin 3D printer can produce detailed prints at a speed of around 30-40mm per hour. So, while you’re waiting for your print to finish, you can take a quick power nap or catch up on your favorite TV show!

How many Minis can you print with 1kg of resin

Ah, the eternal question of resin enthusiasts! The number of Minis you can print with 1kg of resin depends on the size and complexity of your Miniature models. Typically, you can expect to print around 6 to 10 medium-sized Minis with that amount of resin. Of course, this can vary based on your printer’s settings and the level of detail you desire. So, get ready to embark on epic quests with your heroic resin Minis!

Is 3D resin strong

Absolutely! 3D resin is as strong as a grizzly bear wrestling a T-Rex (figuratively, of course)! When cured properly, resin prints can rival the strength of traditional plastic materials. However, it’s essential to choose the right resin for your specific application. Understanding the different resin properties and selecting the appropriate one will ensure that your prints can withstand the test of time. So, go ahead and build a resin empire with confidence!

Do SLA prints shrink

Oh, shrinks! They sound like characters straight out of a hit sitcom. But fear not, when we talk about 3D printing, shrinkage is a reality. SLA (Stereolithography) prints can experience a slight shrinkage during the curing process. However, with modern resin formulations and improved printer calibration, the level of shrinkage has been significantly reduced. So, while your prints might still channel their inner Alice in Wonderland, it won’t be a drastic change. Keep calm and print on!

Is resin cheaper than filament

Ah, the battle of the 3D printing titans! When it comes to cost, resin and filament have their own game plans. While the initial investment for a resin printer can be higher, resin prints typically require less material compared to filament prints. Additionally, resin prints often have quicker print times, reducing electricity costs. So, in the long run, resin prints can be more budget-friendly. Just remember, saving money allows you to splurge on those extra little luxuries in life!

Which resin is the strongest

Get your muscles ready because “Titan Resin” is here to deliver the knockout punch in the strength department! It is known as one of the strongest resins available in 2023. Titan Resin is designed to be incredibly tough, making it perfect for demanding applications such as functional prototypes, mechanical parts, and even large-scale prints. So, if you want your prints to flex their muscles, Titan Resin is the way to go!

Can I leave resin in the vat

Leaving resin in the vat is a big no-no! Resin, when left sitting in the vat for extended periods, can become hardened and unusable. It’s like leaving a milkshake out in the sun—nobody wants a chunky milkshake, right? To keep your resin fresh and your prints top-notch, always remove the excess resin from the vat after printing. It’s a small but essential step to maintain the quality of your resin prints. Goodbye chunky milkshakes, hello crystal-clear prints!

Is casting resin durable

Indeed, casting resin is as durable as a trusty suit of armor! Casting resin is specifically formulated to create sturdy and long-lasting objects, including jewelry, decorative items, and even sculptures. With its excellent detail reproduction and robust properties, casting resin will ensure that your creations stand the test of time. So, let your imagination run wild and cast your worries aside!

Are resin 3D prints stronger than PLA

When it comes to the strength showdown between resin 3D prints and PLA, resin takes the crown! Resin prints have superior strength compared to PLA (Polylactic Acid) prints. Resin’s composition and curing process result in prints that can withstand more stress and impact without cracking or breaking. So, if you’re searching for that rock-solid durability, resin prints are the way to go. It’s time to say goodbye to brittle prints and embrace the strength of resin!

Is it OK to leave resin in the vat

Leaving resin in the vat is like leaving your smartphone plugged in all day—it’s just not a good idea! Over time, the uncured resin can solidify and become a real headache to clean. To keep your resin printer happy and avoid unnecessary mess, always remove the excess resin from the vat after you finish printing. It may take an extra minute or two, but your future self will thank you for it. And remember, friends don’t let friends leave resin in the vat!

How strong is 3D printed material

Hold onto your hats because 3D printed material is no pushover! Depending on the specific material and printing process, 3D printed objects can vary in strength. However, with the continuous advancement of technology, 3D printed materials can tackle challenging tasks with gusto! These materials can be as strong as traditionally manufactured objects, making them suitable for a wide range of applications. So, get ready for prints that can stand tall and proud!

How strong is resin 3D prints

Resin 3D prints are stronger than a bull on steroids! When properly cured and processed, resin prints can exhibit remarkable strength and durability. They can withstand impacts, torsion, and other forces without losing their structural integrity. Whether you’re making functional parts or delicate artistic creations, resin prints will impress you with their strength. So, jump into the resin printing trend and experience the incredible power of these miniature wonders!

Which is better plastic or resin

Plastic or resin? It’s like choosing between peanut butter and jelly—both are delicious in their own way! Plastic (usually referring to filament-based 3D printing materials) and resin have different strengths and applications. Plastic is versatile, relatively inexpensive, and widely available. On the other hand, resin offers superior detail reproduction, smoother finishes, and higher strength. The choice depends on your specific needs and preferences. So, pick your favorite flavor and let your creativity soar!

What is the toughest resin

When it comes to toughness, “Mega Strong Resin” reigns supreme! Mega Strong Resin is specially engineered to provide exceptional toughness and resistance to extreme conditions. Whether you need to withstand harsh outdoor environments or create impact-resistant prototypes, Mega Strong Resin is your go-to. So, buckle up and get ready for resin prints that can tackle any challenge like a boss!

How loud are resin printers

Resin printers are generally quieter than a library mouse practicing yoga! Compared to their FDM (Fused Deposition Modeling) counterparts, resin printers operate with minimal noise. You can enjoy the symphony of silence while your resin printer works its magic, layer by layer. So, sit back, relax, and let your imagination roam free without any noisy distractions!

How do you stop a 3D printer from cracking

Cracking the code to prevent 3D printer cracks? We have the answer! To prevent cracking, it’s vital to ensure proper print settings and optimum curing conditions. Adjusting the orientation, adding supports, and optimizing temperature and exposure settings can help reduce the risk of cracking. Additionally, using resins with improved flexural strength can enhance the print’s overall durability. Remember, a little extra thought and preparation can keep those cracks at bay!

How tough is tough resin

Tough resin is like a superhero defending your prints against the forces of evil! Tough resin materials are specifically designed to possess high stiffness and impact resistance. They can handle rigorous applications, offering outstanding toughness in challenging environments. So, when you need a resin that can put on its cape and save the day, tough resin is there to protect!

Why are my resin prints cracking

Oh no! Cracks have invaded your resin prints, ruining the parade. But fear not, brave adventurer! Cracking in resin prints can occur due to various reasons, such as incomplete curing, excessive exposure to UV light, or improper print settings. To defeat these pesky cracks, ensure sufficient curing time, proper calibration, and compatible resin/print settings. By vanquishing these villains, you’ll be able to enjoy flawless and crack-free resin prints!

How long do resin 3D prints last

Prepare for the marathon of prints because resin 3D prints are built to last! When properly cured and handled, resin prints can last for several years or even decades. Environmental factors such as exposure to UV light and extreme temperatures can impact their longevity. However, with proper care and occasional maintenance, your resin prints will reward you with lasting beauty and durability. So, let your imagination roam free, knowing that your resin prints will stand the test of time!

Is UV resin strong

UV resin is like a little jar of sunshine bursting with strength! UV resin, when cured under UV light, transforms into a durable and robust material. It exhibits excellent resistance to impact, heat, and UV radiation. This strength makes UV resin ideal for a wide range of applications, including jewelry, crafts, and small functional parts. So, get ready to harness the power of the sun and let your UV resin prints shine bright!

How toxic is 3D resin

No need to be worried, my friend! In recent years, significant progress has been made in reducing the toxicity of 3D resins. However, it’s crucial to follow proper handling guidelines and take necessary safety precautions. Always ensure proper ventilation, wear appropriate personal protective equipment (PPE), and dispose of waste responsibly. By being smart and cautious, you can enjoy the world of resin printing while keeping any potential risks at bay!

And there you have it, a comprehensive FAQ that answers all your burning questions about the strength and durability of resin 3D prints. Now, armed with this knowledge, you can dive headfirst into the world of resin printing and create impressive, robust, and long-lasting masterpieces. Happy printing!