We live in a world where technology keeps advancing at an incredible pace. One such technological advancement that has gained significant attention in recent years is 3D printing. From creating small trinkets to building intricate architectural models, 3D printers have revolutionized the way we bring our ideas to life. But have you ever wondered just how fine of detail a 3D printer can actually produce?

In this blog post, we will explore the capabilities of 3D printers in terms of detail and precision. We will delve into the factors that affect the level of detail achievable, such as the type of 3D printing technology used and the materials involved. Additionally, we will address common questions, such as the difference between SLA and DLP 3D printing, the shrinkage of printed parts, and how to ensure the accuracy and precision of your prints. So, grab a cup of coffee and join us as we dive into the fascinating world of 3D printing and the fine details it can achieve.

Keywords: How strong are 3D printed parts?, What is the difference between SLA and DLP 3D printing?, What is a good tolerance for 3D printing?, How much does PLA expand when heated?, What is DLP printing?, How much do 3D prints shrink?, What are the disadvantages of 3D printing?, Are 3D printers illegal?, How do I check the accuracy of a 3D printer?, Does PETG shrink more than PLA?, What type of 3D printing gives the most detail?, Why did my 3D print shrink?, How do you increase the precision of a 3D printer?, Can a 3D printer print everything?, What type of printer might be well suited for smooth fine detail prints in a small build platform?, How do you build a tolerance to a 3D printer?, Can 3D printers print metal?, What type of 3D printer has the best resolution?, What can a 3D printer not make?, How precise can a 3D printer print?, How detailed can a 3D printer get?

How Fine of Detail Can a 3D Printer Print In

Have you ever wondered just how finely detailed a 3D printer can print? Well, you’re about to find out! In this section, we’ll delve into the fascinating world of 3D printing and explore the incredible level of detail that these remarkable machines are capable of achieving.

The Nitty-Gritty of Detail

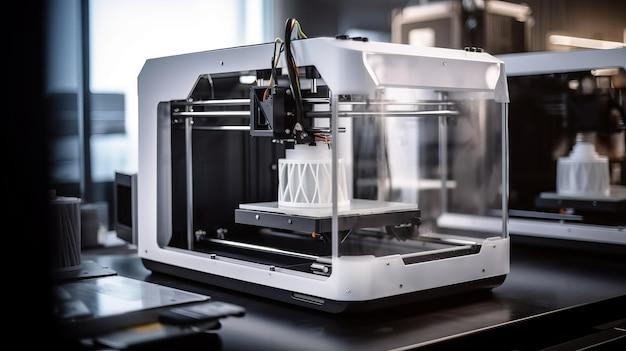

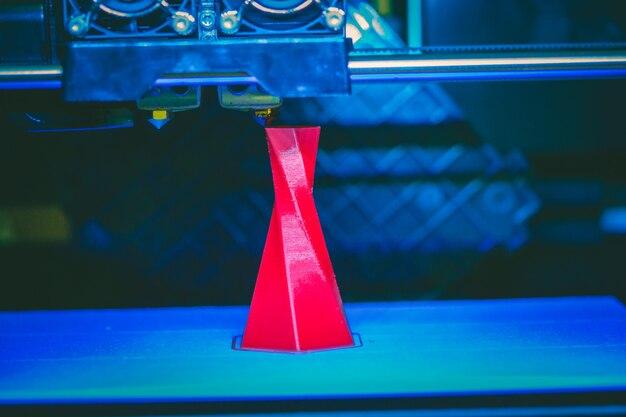

When it comes to the fine art of 3D printing, precision is the name of the game. These cutting-edge printers utilize a process called layer-by-layer additive manufacturing to create objects. Each layer is meticulously crafted by depositing thin layers of material on top of one another until the final product is complete.

Unveiling the Microns

Now, let’s talk numbers! The level of detail that a 3D printer can achieve is often measured in microns. Just to put things into perspective, a single micron is equivalent to one-millionth of a meter. That’s right, we’re talking about incredibly small measurements!

Pushing the Boundaries

So, how fine can a 3D printer actually print? Well, the answer can vary depending on several factors such as the technology used, the type of material being printed, and the specific printer settings. However, as of 2023, 3D printers can achieve layer heights as low as 25 microns (0.025mm)!

A Spiderweb of Detail

To give you a better idea of just how fine this level of detail is, let’s visualize it. Think about the delicate strands of a spiderweb, which are usually around 3-8 microns in diameter. Now, imagine a 3D printer recreating that intricate webbing with a level of precision that rivals the craftsmanship of a master spider! It’s mind-boggling, isn’t it?

Capturing the Imagination

The ability of 3D printers to produce intricate and highly detailed objects opens up a world of possibilities. From architectural models to jewelry and even prosthetic limbs, the level of detail achievable by these machines allows for the creation of truly captivating and lifelike representations.

The Future of Fine Detail

As technology continues to advance at a breakneck pace, it’s only a matter of time before the level of detail achievable by 3D printers reaches even greater heights. Who knows, in the near future, we might witness printers that can recreate minute details that are indistinguishable from reality itself.

Summary

In conclusion, the fine detail that a 3D printer can achieve is nothing short of extraordinary. With the ability to print with layer heights as low as 25 microns, these printers are capable of producing objects that rival the intricacy of even the most delicate spiderweb. The future holds endless possibilities as we continue to push the boundaries of what is possible with 3D printing technology. So, sit back, buckle up, and get ready to be amazed by the microscopic level of detail that these printers can bring to life!

FAQ: How Fine Of Detail Can A 3D Printer Print In

Welcome to our FAQ section on the fine detail capabilities of 3D printers! You’ve got questions, and we’ve got answers. Let’s dive right in and uncover the fascinating world of 3D printing.

How strong are 3D printed parts

3D printed parts can vary in strength depending on the material used and the printing process. Generally, parts printed with materials like ABS and PETG are stronger than those printed with PLA. However, it’s important to note that 3D printed parts may not have the same strength as traditionally manufactured parts. So while they can be strong enough for many applications, they may not be suitable for high-stress situations like heavy load-bearing.

What is the difference between SLA and DLP 3D printing

SLA (Stereolithography) and DLP (Digital Light Processing) are both resin-based 3D printing technologies, but they differ in how they cure the resin. SLA printers use a laser to selectively cure liquid resin layer by layer, while DLP printers use a digital light projector to flash an entire layer at once. This means that DLP printers can often print faster than SLA printers. However, SLA printers tend to produce more accurate prints and can achieve finer levels of detail.

What is a good tolerance for 3D printing

Tolerance refers to the accuracy or precision of a 3D printed part. A good tolerance for 3D printing depends on various factors such as the printer type, the material being used, and the specific requirements of the project. In general, a tolerance of around ±0.1mm is considered achievable for most consumer-grade 3D printers. However, high-end printers can achieve even tighter tolerances.

How much does PLA expand when heated

PLA (Polylactic Acid) is known for its low thermal expansion properties compared to other 3D printing materials. It expands relatively little when heated, usually around 0.05% linear expansion between room temperature and its glass transition temperature of around 60-65°C (140-149°F). This makes PLA a popular choice for printing fine details that require dimensional accuracy.

What is DLP printing

DLP (Digital Light Processing) printing is a resin-based 3D printing technology that uses a digital light projector to cure liquid resin layer by layer. It works by projecting a pattern of UV light onto the resin, causing it to solidify. DLP printers can produce high-resolution prints with smooth surface finishes and are often used in applications where fine detail is crucial, such as jewelry making and dental prosthetics.

How much do 3D prints shrink

Shrinkage is a natural occurrence in 3D printing due to the cooling and solidification of the materials. The amount of shrinkage depends on various factors, including the material being used. Generally, PLA experiences less shrinkage than materials like ABS. It is recommended to factor in shrinkage when designing 3D printed parts to ensure the final dimensions align with the desired specifications.

What are the disadvantages of 3D printing

While 3D printing offers many benefits, it does have some limitations. Some disadvantages include:

- Limited material options compared to traditional manufacturing processes.

- Relatively slow print times (especially for complex and highly detailed models).

- Post-processing requirements to achieve desired finishes.

- Higher cost of printers and materials compared to traditional manufacturing methods for large-scale production.

- Limited strength and durability compared to traditionally manufactured parts.

Are 3D printers illegal

No, 3D printers themselves are not illegal. However, the use of 3D printers to create certain objects may be subject to legal restrictions. For example, printing copyrighted objects without permission or printing firearms may be illegal in many jurisdictions. It’s important to understand and comply with the laws and regulations in your area when using a 3D printer.

How do I check the accuracy of a 3D printer

To check the accuracy of a 3D printer, you can perform a calibration test. This involves printing a test object with known dimensions and comparing the printed dimensions to the intended dimensions. By measuring the differences, you can assess the accuracy of the printer. Additionally, using specialized calibration tools and software can help fine-tune the printer’s performance and ensure optimal accuracy.

Does PETG shrink more than PLA

PETG (Polyethylene terephthalate glycol) generally experiences less shrinkage compared to PLA. While both materials can exhibit shrinkage during the printing process, PETG has a lower coefficient of thermal expansion, meaning it undergoes less dimensional change when exposed to temperature variations. This makes PETG a good choice for parts that require minimal post-printing adjustments.

What type of 3D printing gives the most detail

When it comes to achieving the highest level of detail in 3D printing, SLA (Stereolithography) stands out. SLA printers are known for their ability to produce incredibly detailed prints with smooth surface finishes. Their fine resolution allows for intricate details and precise geometries, making SLA a popular choice in fields such as jewelry design, small-scale prototyping, and artistry.

Why did my 3D print shrink

Shrinkage is a common occurrence in 3D printing due to material cooling and solidification. Several factors can contribute to excessive shrinkage, including environmental conditions, improper printer calibration, incorrect material settings, and poor design choices. It’s important to consider these factors and make adjustments to optimize the printing process and minimize shrinkage.

How do you increase the precision of a 3D printer

To increase the precision of a 3D printer, there are several steps you can take:

- Calibrate the printer regularly to ensure accurate movement and positioning.

- Use high-quality filament and set appropriate printing parameters.

- Optimize the printer’s cooling system to minimize warping and distortion.

- Fine-tune the slicer settings to achieve the desired level of detail.

- Consider upgrading to a printer with a higher resolution or more precise components.

- Implement proper maintenance and cleanliness practices to avoid performance degradation over time.

Can a 3D printer print everything

While 3D printers are incredibly versatile tools, they do have limitations. They cannot print objects that exceed the build volume of the printer, and certain complex geometries may be challenging to print accurately. Additionally, the availability of suitable materials for printing specific objects can also limit the range of printable items. It’s essential to consider these factors when determining if a 3D printer is suitable for a particular project.

What type of printer might be well suited for smooth fine detail prints in a small build platform

When it comes to achieving smooth fine detail prints in a small build platform, SLA (Stereolithography) printers are an excellent choice. Their ability to produce high-resolution prints with intricate details makes them ideal for projects that require precision and aesthetics. With SLA printers, you can achieve smooth surfaces and capture even the tiniest of details, enabling you to bring your designs to life in stunning clarity.

How do you build a tolerance to a 3D printer

Building tolerance to a 3D printer involves understanding its capabilities and limitations and making necessary adjustments. Here’s how you can work towards building a tolerance:

- Calibration: Regularly calibrate your printer to ensure accurate movement and positioning.

- Printer Settings: Fine-tune temperature, fan speed, and other settings to optimize print results.

- Design Considerations: Adapt your designs to accommodate the printer’s precision and limitations.

- Material Selection: Choose materials that are suitable for achieving the desired tolerances.

- Iterative Process: Test and adjust settings, design, and materials to refine the printing process and achieve the desired results.

Can 3D printers print metal

Yes, 3D printers can print metal objects using specialized technologies like Metal Additive Manufacturing (MAM). These printers use metal powders and a laser or electron beam to selectively melt and fuse the powders together, layer by layer, to create metal objects. Metal 3D printing is gaining popularity in industries such as aerospace, automotive, and medical, where strength, complexity, and customization are crucial.

What type of 3D printer has the best resolution

SLA (Stereolithography) printers are known for their exceptional resolution capabilities. They use a laser to cure liquid resin layer by layer, resulting in highly detailed prints with smooth surface finishes. SLA printers can achieve resolutions as fine as 25 microns (0.025mm), allowing for intricate and precise designs.

What can a 3D printer not make

While 3D printers are incredibly versatile, there are some limitations to what they can create. They struggle with printing objects with large unsupported overhangs or intricate internal cavities. Additionally, certain complex mechanical systems or objects requiring multiple materials or moving parts may be challenging to print accurately with a standard 3D printer. However, advancements in technology continue to push these boundaries, and new techniques and materials are constantly being developed.

How precise can a 3D printer print

The precision of a 3D printer depends on various factors, including the printer type, calibration, print settings, and material properties. High-quality desktop printers can typically achieve a precision of around 0.1mm or better, with professional-grade printers capable of even finer levels of precision. However, it’s essential to note that achieving optimal precision also relies on factors such as design considerations and proper printer maintenance.

How detailed can a 3D printer get

The level of detail a 3D printer can achieve depends on factors such as printer resolution, material properties, and printer stability. High-end printers with fine resolution capabilities can produce prints that capture intricate details, such as fine texture, embossed patterns, and even small engravings. However, it’s important to consider the limitations of the chosen printer and material when pushing for finer levels of detail.

That concludes our FAQ section on the fine detail capabilities of 3D printers. We hope we’ve provided you with valuable insights and answered your burning questions. Happy printing and remember, the sky’s the limit (well, the build volume is, actually) when it comes to unleashing your creativity with 3D printing!