Welcome to our comprehensive blog post on the topic of AC motors and brushes. In this article, we will dive deep into the world of motors, examining whether all AC motors have brushes or if there are exceptions to this rule. If you’ve ever wondered about the differences between brushed and brushless motors, or if you’re curious about how to identify if your motor’s brushes are worn out, you’ve come to the right place!

Throughout this blog post, we will address common questions such as whether a DC motor can run on AC, the self-starting capabilities of a 3-phase induction motor, and the various motor controls available. We will also explore the advantages and disadvantages of brushed and brushless motors, their power levels, longevity of brushes, and much more. So, whether you’re a motor enthusiast, a DIY hobbyist, or simply intrigued by the inner workings of these machines, join us as we unravel the mysteries of AC motors and brushes.

Keywords: Can I replace a brushed motor with a brushless motor?, Can a DC motor run on AC?, Does a permanent magnet motor have brushes?, Is a 3-phase induction motor self-starting?, How do I know if my electric motor brushes are bad?, Why do DC motors have brushes?, Do 3-phase motors have brushes?, How do I know if my engine has brushes?, Are brushed motors better than brushless?, What motors have brushes?, What happens when motor brushes wear out?, Which motor does not have brushes?, How can a motor be made more powerful?, How long do motor brushes last?, Why do motors need brushes?, Do any AC motors have brushes?, What are 3 types of motor controls?, What happens if carbon brushes are worn?, How do I test my brushes?, Why does an AC motor not need a commutator?, What happens when you reverse polarity in a motor?, Are brushless motors more powerful than brushed?

Do AC Motors Wear Makeup

AC motors, those trusty electrical wonders that power everything from ceiling fans to industrial machinery, are truly fascinating pieces of technology. But one question that often pops up when discussing these motors is whether they all have brushes. So, let’s clear the air and find out!

The Brush Myth: Debunked!

Contrary to popular belief, not all AC motors wear makeup brushes or any other kind of brush for that matter. While some types of motors, such as DC motors, do utilize brushes to facilitate their operation, AC motors follow a different set of rules.

Meet the Brushless Wonder

One of the main advantages of AC motors is their ability to operate without brushes. AC induction motors, the most common type of AC motor, are brushless wonders. Instead of brushes, they rely on electromagnetic induction to create the rotating magnetic field essential for their functionality. This ingenious design eliminates the need for brushes, making AC motors more reliable and requiring less maintenance compared to their brush-laden counterparts.

Brush Those Worries Away!

Brushes in motors can be a cause of concern due to their wear and tear. Over time, brushes may wear out, requiring replacement. This maintenance task can be a hassle, not to mention the potential for downtime and additional costs. Thankfully, AC motors spare us from such inconveniences, as they have successfully rid themselves of the burden of brushes.

The Silent Performers

Another advantage of brushless AC motors is their quieter operation. Without the friction and sparking caused by brushes, AC motors can hum along smoothly, quietly doing their job without any unnecessary commotion. So, whether you’re enjoying a peaceful night’s sleep undisturbed by abrasive motor noise or working in a noise-sensitive environment, brushless AC motors are the silent performers you’ll want keeping things running smoothly.

Efficiency: AC Motors’ Secret Superpower

Brushless AC motors also excel in the efficiency department. The absence of brushes significantly reduces energy losses and increases the overall efficiency of the motor. This means that a brushless AC motor can convert more electrical energy into useful mechanical energy, resulting in cost savings and a greener footprint. So not only are these motors reliable and low-maintenance, but they’re also eco-friendly powerhouses!

Goodbye, Brushes!

In conclusion, when it comes to AC motors, most of them wave goodbye to brushes. AC induction motors, the common AC motor type, have done away with brushes thanks to their brushless design. This innovation brings about numerous benefits, including enhanced reliability, reduced maintenance, quieter operation, and improved efficiency. So, next time you see an AC motor, you can confidently say, “Nope, no makeup brushes needed here!”

FAQ: Do All AC Motors Have Brushes

Can I Replace a Brushed Motor with a Brushless Motor

Yes, you can replace a brushed motor with a brushless motor, but it’s not always a simple swap. Brushed motors have brushes that make direct contact with the commutator, while brushless motors use electronic commutation. The wiring and control systems for brushless motors are different, so you may need to make adjustments or get professional help to ensure compatibility.

Can a DC Motor Run on AC

No, DC motors are designed to run on direct current (DC) power, which flows in one direction. AC motors, on the other hand, are designed to run on alternating current (AC) power, which switches direction periodically. If you try to run a DC motor on AC power, it will not function properly and may even be damaged.

Does a Permanent Magnet Motor Have Brushes

No, permanent magnet motors do not have brushes. These motors use a permanent magnet to create a magnetic field, eliminating the need for brushes and a commutator. The absence of brushes can make permanent magnet motors more efficient and reliable compared to brushed motors.

Is the 3-Phase Induction Motor Self-Starting

Yes, the 3-phase induction motor is self-starting, which means it can start and run without the need for external aids or manual intervention. The motor relies on the rotating magnetic field generated by the combination of three-phase AC power and the stator windings to start and operate.

How Do I Know if My Electric Motor Brushes Are Bad

There are a few signs that indicate your electric motor brushes may be bad. One common symptom is a noticeable decrease in motor performance or power output. You may also hear unusual sounds, such as sparking or scraping noise, coming from the motor. In some cases, the motor may even fail to start or experience intermittent operation. If you suspect that your brushes are bad, it’s best to consult a professional for inspection and possible replacement.

Why Do DC Motors Have Brushes

DC motors have brushes to facilitate the transfer of electrical current between the stationary parts (stator) and the moving parts (rotor) of the motor. Brushes make direct contact with the commutator, which is a segmented metal ring attached to the rotor. As the commutator rotates, the brushes maintain contact, allowing the flow of current and enabling the motor’s operation.

Do 3-Phase Motors Have Brushes

No, 3-phase motors typically do not have brushes. These motors often use a squirrel cage rotor design, where the rotor has conductive bars that create a magnetic field in response to the 3-phase AC power supplied to the stator windings. As a result, 3-phase motors do not require brushes or commutators for operation.

How Do I Know if My Engine Has Brushes

Engines, unlike electric motors, do not have brushes. Engines, such as those found in vehicles or machinery, rely on fuel combustion to generate power, whereas electric motors use electrical energy to produce rotational force. Therefore, if you are dealing with an engine, you can be confident that it does not have brushes.

Are Brushed Motors Better Than Brushless

The answer depends on the specific application and requirements. Brushed motors are known for their simplicity and affordability, but they tend to be less efficient, produce more heat, and require periodic maintenance due to brush wear. On the other hand, brushless motors are generally more efficient, produce less heat, require less maintenance, and offer better speed control. However, brushless motors are typically more expensive. So, it’s essential to consider factors such as cost, efficiency, maintenance needs, and performance when determining which motor type is better for your specific needs.

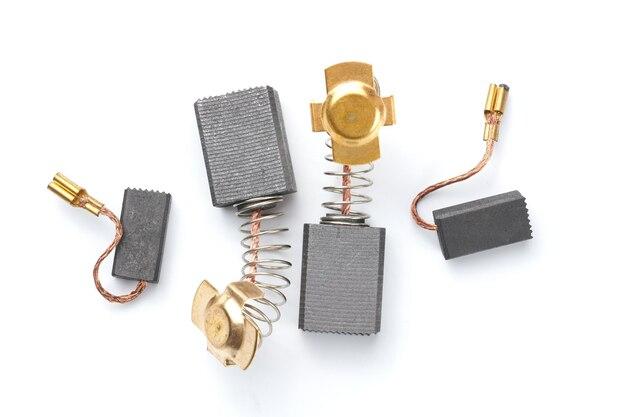

What Motors Have Brushes

Various motors can have brushes, including brushed DC motors, universal motors, and some types of AC motors, such as single-phase induction motors and commutator motors. These motors use brushes and a commutator to facilitate the transfer of electrical current.

What Happens When Motor Brushes Wear Out

When motor brushes wear out, their contact with the commutator becomes less effective, leading to decreased motor performance, increased heat generation, and potential damage to the commutator itself. In some cases, worn-out brushes may cause the motor to stop working altogether. Regular inspection and replacement of brushes are necessary to maintain optimal motor functioning.

Which Motor Does Not Have Brushes

Brushless motors are the ones that do not have brushes. These motors use electronic commutation to control the flow of current, eliminating the need for brushes. Brushless motors are commonly found in applications where efficiency, precision, and reliability are crucial, such as electric vehicles, drones, and industrial automation.

How Can a Motor Be Made More Powerful

There are a few ways to make a motor more powerful. One option is to increase the voltage or current supplied to the motor, which can enhance its torque and output power. Another approach is to improve the motor’s design and construction, such as using better quality materials, optimizing winding configurations, or enhancing cooling mechanisms. However, it’s important to note that modifying a motor to increase power should be done with caution and expertise to avoid damage or safety risks.

How Long Do Motor Brushes Last

The lifespan of motor brushes depends on various factors, such as the motor type, operating conditions, and maintenance practices. On average, motor brushes can last anywhere from several hundred to several thousand hours of operation. Regular inspection and replacement, when necessary, can help ensure optimal brush performance and extend motor life.

Why Do Motors Need Brushes

Motors need brushes because they enable the transfer of electrical current between the stationary and moving parts of the motor. By maintaining contact with the commutator or rotor, brushes ensure the flow of current, which creates the necessary magnetic field and rotational force. Without brushes, the efficiency and functionality of the motor would be compromised.

Do Any AC Motors Have Brushes

While most AC motors do not have brushes, some types of AC motors, such as single-phase induction motors and commutator motors, may use brushes. These motors rely on brushes to facilitate the transfer of electrical current, ensuring proper motor operation. However, it’s worth noting that brushless AC motors are becoming increasingly popular due to their improved efficiency and reliability.

What Are Three Types of Motor Controls

Three common types of motor controls are Direct On Line (DOL) starters, Star-Delta starters, and Variable Frequency Drives (VFDs). DOL starters provide a direct connection between the motor and the power source, while Star-Delta starters reduce starting current by initially connecting the motor in a star configuration and then switching to a delta configuration. VFDs, also known as inverters, allow for precise control and adjustment of motor speed and torque by varying the frequency and voltage supplied to the motor.

What Happens if Carbon Brushes Are Worn

When carbon brushes become worn, their ability to maintain proper contact with the commutator or rotor is compromised. This can result in decreased motor performance, increased arcing or sparking, excessive heat generation, and potential damage to the commutator or rotor surface. Regular inspection and replacement of worn carbon brushes are crucial to ensure optimal motor functioning and extend its lifespan.

How Do I Test My Brushes

To test motor brushes, you can follow these steps:

- Disconnect the motor from the power source.

- Remove the brush caps or access covers.

- Inspect the brushes for any signs of wear, damage, or irregularities.

- Use a multimeter to measure the continuity or resistance of the brushes. A low resistance reading indicates good brush contact.

- Gently clean the brushes and commutator to remove any debris or carbon buildup.

- Reinstall the brushes and test the motor’s operation.

Why Does an AC Motor Not Need a Commutator

AC motors do not require a commutator because the alternating current itself changes direction periodically. This alternating direction of the current induces a rotating magnetic field in the motor’s stator windings, which in turn causes the rotor to rotate. The absence of a commutator in AC motors simplifies their design, reduces maintenance needs, and enhances overall reliability.

What Happens When You Reverse Polarity in a Motor

If you reverse the polarity of a motor, meaning you swap the connections that provide the positive and negative power supply, the motor will rotate in the opposite direction. This reversal of polarity changes the direction of the magnetic field generated by the motor, resulting in a reverse rotation. Reversing the polarity can be useful for certain applications or when a motor is connected incorrectly, but it should be done with caution to avoid any adverse effects.

Are Brushless Motors More Powerful Than Brushed

In general, brushless motors have the potential to be more powerful than brushed motors. Brushless motors typically offer higher power-to-weight ratios, improved efficiency, and better speed control. Without brushes, brushless motors can achieve higher rotational speeds and generate more torque, making them suitable for demanding applications that require high performance. However, the specific power capabilities of a motor depend on various factors, including its design, size, and intended use.