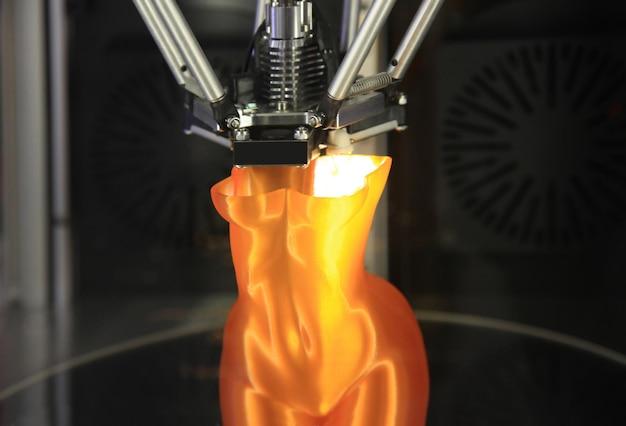

In the ever-evolving world of 3D printing, enthusiasts and professionals are constantly seeking ways to enhance the versatility and strength of 3D printed parts. One popular question that arises is whether JB Weld, a renowned adhesive brand, can be used to bond and repair 3D printed parts. If you’ve been dabbling in 3D printing or are considering it as a new venture, this blog post will address the effectiveness of JB Weld on various 3D printed materials, such as PLA and PETG.

We’ll explore common issues like joining PLA parts, repairing PLA prints, and understanding the compatibility of JB Weld with PLA and PETG. Additionally, we’ll delve into alternative methods for fusing 3D printed parts and strengthening them for optimal durability. So, if you’re curious about optimizing your 3D printed projects or encountering challenges in this realm, keep reading to discover some valuable insights and expert recommendations on the subject.

Does JB Weld Work on 3D Printed Parts

If you’re a fan of 3D printing, you know the joy of creating something unique and custom-made. However, 3D printed parts can sometimes be delicate and prone to breaking. That’s where JB Weld comes in! But the question remains: does this magical adhesive really work on 3D printed parts? Let’s find out!

The Magic of JB Weld

JB Weld is a brand of epoxy adhesive known for its strong bonding properties. It’s like the superhero of glues, capable of fixing almost anything. And that includes 3D printed parts!

The Perfect Match

When it comes to 3D printed parts, the material used for printing plays a crucial role in determining the compatibility with adhesives like JB Weld. So before you go wild with the epoxy, check the type of filament used for your 3D print.

PLA: A Promising Pairing

One of the most popular 3D printing materials is PLA (polylactic acid). Luckily, JB Weld tends to work well on PLA parts. The epoxy can bond PLA effectively and provide the strength needed to keep your creation intact.

ABS: A Tricky Situation

ABS (acrylonitrile butadiene styrene) is another common material used for 3D printing. JB Weld may not be the best option for ABS parts due to the material’s high level of flexibility. While the adhesive might provide temporary bonding, it may not withstand the constant strain and stress ABS parts can experience.

Nylon: A Tough Nut to Crack

If you’re working with nylon 3D printed parts, you might have a harder time finding a reliable adhesive. JB Weld may not bond as effectively with nylon due to its low surface energy. However, there are specialized adhesives formulated specifically for bonding nylon that you can explore.

The JB Weld Application Process

To ensure a successful bond between JB Weld and your 3D printed parts, preparation is key. First, clean and dry the surfaces to be glued. Roughening the surfaces slightly can enhance adhesion. Then, mix the epoxy adhesive according to the instructions on the package, and apply it evenly to the surfaces you want to bond. Finally, clamp the parts together and let the adhesive cure for the recommended amount of time.

A Word of Caution

While JB Weld is a great adhesive, it’s important to remember that it’s not a magic fix for every situation. Factors such as surface area, design complexity, and stress points on your 3D printed parts can affect the overall bond strength. It’s always a good idea to test the adhesive on a small, inconspicuous area before committing to a full-scale repair.

In the exciting world of 3D printing, JB Weld can be a reliable companion when it comes to bonding and repairing your creations. With its strength and versatility, it’s a good option, especially for PLA parts. Just be mindful of the material used for your 3D printed parts and the specific requirements they may have. So go ahead, embrace the power of JB Weld, and let your creativity soar!

FAQ: Does JB Weld Work on 3D Printed Parts

Can you use JB Weld on PLA

Yes, you can use JB Weld on PLA 3D printed parts. JB Weld is a versatile epoxy adhesive that can bond various materials, including PLA. It creates a strong and durable bond, making it a reliable option for repairing or joining PLA prints.

How do you repair PLA prints

To repair PLA prints, you can use JB Weld or other epoxy adhesives. Start by preparing the damaged area by sanding it lightly to remove any rough edges. Mix the epoxy according to the manufacturer’s instructions and apply it to the damaged area. Hold the parts together firmly until the epoxy sets and cures. After curing, you can further sand and paint the repaired part if needed.

How do you join two PLA parts

When joining two PLA parts, JB Weld can be the go-to adhesive. Begin by roughening the bonding surfaces of the PLA parts with sandpaper to enhance adhesion. Apply a thin layer of JB Weld epoxy to one of the bonding surfaces and press the two parts firmly together. Allow the epoxy to cure completely as per the manufacturer’s instructions before further handling or stress on the joint.

Does PETG melt in acetone

No, PETG does not melt in acetone. Unlike some other plastics, PETG is resistant to acetone and cannot be dissolved or melted by it. If you need to clean or smooth PETG prints, you should use other methods such as sanding or polishing.

How do you fuse 3D printed parts

To fuse 3D printed parts, you can use methods like solvent welding or epoxy bonding. Solvent welding involves using a specific solvent for the 3D printed material, such as acetone for ABS, to partially dissolve the surface layers and create a strong bond when the parts are pressed together. Epoxy bonding, on the other hand, involves using a strong epoxy adhesive like JB Weld to join the parts together.

How do you melt PLA

To melt PLA, you need to heat it to its melting point. PLA has a relatively low melting point compared to other 3D printing filaments. You can use a 3D printer with a heated bed and extruder to melt and shape PLA. Alternatively, you can use a heat gun or oven to melt PLA, but be cautious to avoid overheating or damaging the material.

What is the best glue for PLA

JB Weld is a popular and reliable choice for gluing PLA parts together. Its strong epoxy formula ensures a durable bond. Other options for gluing PLA include cyanoacrylate (super glue) and epoxy putty. Make sure to choose a glue specifically designed for plastics and follow the manufacturer’s instructions for the best results.

Does PLA dissolve in acetone

No, PLA does not dissolve in acetone. Unlike some other plastics, like ABS, PLA is not soluble in acetone. Acetone can be used to clean or smooth PLA prints to some extent, but it will not dissolve the material completely.

Does Gorilla Glue work on 3D prints

Yes, Gorilla Glue can work on 3D prints. Gorilla Glue is a versatile adhesive that can bond various materials, including plastics like PLA and ABS commonly used in 3D printing. It creates a strong bond and is suitable for multiple 3D printing applications.

Can 3D printed parts be strong

Yes, 3D printed parts can be strong and durable depending on the material and printing parameters used. High-quality materials, such as PLA, ABS, or PETG, when printed with proper settings, can produce robust and functional parts. However, the strength of 3D printed parts may still be lower compared to traditionally manufactured objects.

How do you strengthen a 3D printed part

To strengthen a 3D printed part, you can employ several techniques. You can increase the infill density during printing for a more solid internal structure. Choosing a stronger filament, such as PLA+, ABS+, or nylon, can improve the overall strength. Post-processing methods, such as annealing for PLA or acetone vapor smoothing for ABS, can also enhance strength. Additionally, adding reinforcement, like inserting metal rods or using epoxy with fiberglass, can make the part stronger.

Is PLA actually biodegradable

Yes, PLA is considered biodegradable. PLA is made from renewable resources like corn starch or sugarcane, making it a more environmentally friendly material compared to petroleum-based plastics. It is biodegradable under specific industrial composting conditions, but it may take a long time to break down in home composting or natural environments.

How do you smooth PLA 3D printed objects

To smooth PLA 3D printed objects, you can use various methods. Sanding the surface with fine grit sandpaper can help remove layer lines and achieve a smoother finish. Another option is using a heat gun to slightly melt the surface of the PLA, smoothing out imperfections. Chemical smoothing with a mixture of acetone and PLA scraps can also be effective for smoothing PLA prints.

How do you make PLA tougher

There are a few ways to make PLA tougher. One method is annealing, which involves heating the PLA print to a specific temperature and then slowly cooling it down. This process can increase the crystallinity of the PLA, making it stronger. Using PLA blends or copolymers, such as PLA+ or PLA with additives like carbon fiber or glass fiber, can also enhance toughness. Additionally, increasing the thickness or adding reinforcement to critical areas can strengthen the overall part.

Does PVC cement work on PLA

No, PVC cement does not work on PLA. PVC cement is specifically designed for bonding PVC pipes and fittings and is not suitable for bonding PLA or other plastics. For PLA, it is best to use adhesives that are specifically formulated for bonding PLA or other common 3D printing materials.

Does epoxy make 3D prints stronger

Yes, epoxy can make 3D prints stronger. When used as an adhesive or coating, epoxy creates a robust bond and provides additional structural support to 3D printed parts. It can increase the overall strength, durability, and resistance to impact or stress.

Does tacky glue work on PLA

Tacky glue can work on PLA to some extent, but it is not the most ideal option. Tacky glue is typically used for crafts and may not have the strongest bonding properties for PLA. It may be suitable for temporary or low-stress applications, but for stronger and more durable bonds on PLA prints, epoxy adhesives like JB Weld are recommended.

Will fiberglass resin stick to PETG

Yes, fiberglass resin can stick to PETG. PETG is a relatively inert material and is compatible with many adhesives, including fiberglass resin. Before applying the fiberglass resin, make sure to clean and prepare the PETG surface properly to ensure a strong and durable bond.

Does alcohol melt PLA

No, alcohol does not melt PLA. PLA is resistant to alcohol and will not dissolve or melt when exposed to it. However, alcohol can be used as a cleaning agent for removing dust, oils, or residues from PLA prints.

Does PLA react with rubbing alcohol

No, PLA does not have a strong reaction with rubbing alcohol. PLA is generally resistant to rubbing alcohol, and it does not dissolve or damage the material. Rubbing alcohol can be used to clean PLA prints or prepare the surface for techniques like acetone vapor smoothing.

Will epoxy stick to PETG

Yes, epoxy can stick to PETG. PETG is a material that can be effectively bonded with epoxy adhesives. Ensure that the surfaces are clean, and follow the epoxy manufacturer’s instructions for the best adhesion results.

Disclaimer: The information provided in this FAQ-style subsection is for general guidance and informational purposes only. Always refer to the specific instructions and recommendations provided by the manufacturers of the materials and adhesives you intend to use.