Lasers have quickly become a go-to technology for precision cutting in various industries. They offer a level of accuracy and efficiency that is hard to match. But the question remains: can a laser cut through anything?

In this blog post, we will explore the capabilities and limitations of lasers when it comes to cutting different materials. From diamond to acrylic, we will delve into the world of laser cutting and discover what can and cannot be accomplished with this powerful tool.

We will also address common questions about laser cutting, such as the cost of laser devices like Trotec lasers, the difference between plasma cutting and laser cutting, as well as the cutting abilities of lasers with different power ratings. So, fasten your seat belts and get ready for an illuminating journey into the realm of laser cutting!

Can a Laser Cut Through Anything

Have you ever wondered if a laser can cut through anything? Well, prepare to be amazed because lasers are like superheroes in the cutting world. They have the power to slice through a wide range of materials with precision and finesse. But can they really cut through anything? Let’s dive into the world of lasers and find out!

The Power of Lasers

Laser, an acronym for Light Amplification by Stimulated Emission of Radiation, is a beam of concentrated light that can pack quite a punch. This concentrated beam is generated by exciting atoms or molecules to emit photons, creating a highly focused and intense beam of light. In other words, lasers are like a concentrated army of light particles ready to cut through anything that crosses their path.

The Cutting Edge

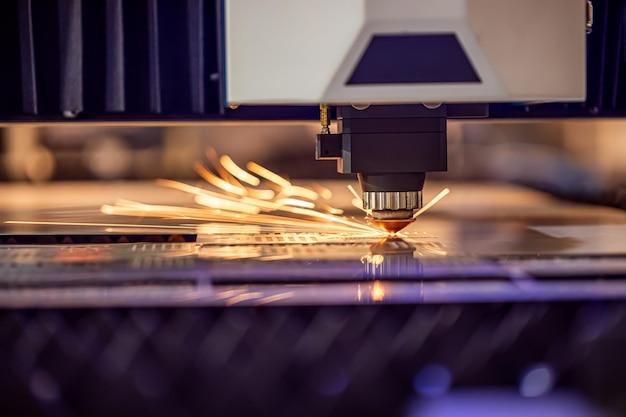

When it comes to laser cutting, the possibilities are nearly endless. Laser cutters can slice through materials such as metals, plastics, wood, fabric, and even diamonds. Yes, you read that right, diamonds! Nothing can stand in the way of a laser beam when it comes to precise and intricate cutting tasks.

Metal: The Mighty Challenger

While lasers have the power to cut through a wide variety of materials, not all substances are created equal. When it comes to cutting metal, lasers are the ultimate warriors. With their incredible focus and intensity, laser beams can slice through metal sheets like a hot knife through butter. From stainless steel to aluminum, lasers can tame even the most stubborn metals with ease.

The Limitations of Light

As powerful as lasers may be, they do have their limitations. For starters, lasers struggle to cut through highly reflective surfaces like mirrors. The intense light beam reflects back on itself, making it difficult to penetrate the surface. Additionally, some materials, such as thick concrete or certain types of ceramics, can pose challenges for lasers due to their high density and composition.

Safety First!

Now, before you go on a laser-cutting spree, it’s important to understand that laser cutting is not child’s play. Proper safety measures must be followed to prevent accidents and injury. Protective eyewear and gloves are a must when handling lasers, as their intense beams can cause damage to the eyes and skin. It’s also crucial to have proper ventilation in place to safeguard against harmful fumes generated during the cutting process.

So, can a laser cut through anything? While lasers possess tremendous cutting capabilities, they do have their limits. They can slice through a vast array of materials, including metals, wood, and even diamonds. However, highly reflective surfaces and dense substances may pose challenges. Remember, lasers are powerful tools that require utmost caution and respect. So, the next time you encounter a laser beam, just remember that it has the potential to conquer a wide range of materials, but it’s not invincible. Stay safe, and let the laser work its magic within its boundaries.

FAQ: Can a laser cut through anything

How much does a Trotec laser cost

The cost of a Trotec laser can vary depending on the model and features. Generally, Trotec lasers range from around $7,000 to $50,000. It’s important to consider your specific needs and budget before investing in a laser cutter. Remember, you’re not just buying a machine, you’re investing in a future of possibilities!

What machine can cut diamond

Diamonds are known for their exceptional hardness, so cutting them requires an equally extraordinary tool. While lasers are incredibly versatile, they can’t cut through diamonds. Instead, a diamond can only be cut by another diamond. It’s like a rock-paper-scissors situation, except with just two materials. So if you find yourself with a diamond in need of cutting, make sure you have a diamond cutter handy – or, you know, hire a professional.

Are Chinese laser cutters any good

Ah, the age-old question. Chinese laser cutters have gained quite a reputation over the years, and, like most things in life, they come with pros and cons. While some Chinese laser cutters offer decent performance at a lower cost, quality control can be hit or miss. It’s important to thoroughly research and read reviews before purchasing one. Remember, it’s not just about nationality—it’s about finding the right laser cutter that suits your needs and budget.

Can a laser cut through anything

While it’s tempting to believe in the magical powers of lasers cutting through anything, sadly, that’s not the case. Laser cutters have limitations, just like everything else in life. They work wonders on materials like wood, acrylic, and metal, but they won’t cut through everything. Thick or highly reflective materials might pose a challenge for laser cutters, so it’s always best to consult the material compatibility guidelines before aiming a laser at it.

How thick can a fiber laser cut

Ah, thickness—the eternal enemy of laser cutters. Fiber lasers are known for their high precision and speed, but when it comes to thickness, they have their limits. Generally, a fiber laser can cut through materials up to a few inches thick, depending on the specific machine and material being cut. Keep in mind that the thicker the material, the more time and power it will require to get the job done. So, if you need to slice through something bulky, make sure to choose the right laser for the thickness!

Is there anything diamond can cut

Ah, the wonders of diamond—nature’s shiny, super-hard material. While diamond has an impressive reputation, there are some materials it can’t quite conquer. Despite its hardness, diamond won’t cut through other diamonds. It’s like having two superheroes battling it out but cancelling each other’s powers. When it comes to diamond, its cutting prowess is mostly reserved for softer materials, making it an ideal tool for industries like gemology and precision cutting.

How thick will a plasma cutter cut

Unlike lasers, which are all about focused light beams, plasma cutters use ionized gas to blast through materials. This gives them an advantage when it comes to thickness. A high-power plasma cutter can handle materials up to a few inches thick, depending on the specific machine and material. So, if you find yourself needing to make some clean, precise cuts in thicker metal, a plasma cutter might just be your knight in shining armor.

Is laser cutting expensive

Ah, the question on everyone’s minds—how much will this magical beam of light cost me? Laser cutting can be a great investment, but like all good things in life, it does come with a price tag. The cost of laser cutting can vary depending on factors such as material, design complexity, machine power, and setup time. While it might not always be the cheapest option, laser cutting offers unparalleled precision and versatility, making it worth considering for projects where quality is of paramount importance.

What is the difference between plasma cutting and laser cutting

Plasma cutting and laser cutting are like two siblings with different skills but equally impressive talents. While they both carve their way through materials, they work in distinct ways. Laser cutters use focused light beams to melt or vaporize materials, resulting in clean, precise cuts. On the other hand, plasma cutters use ionized gas to melt and blow away materials, effectively slicing through thicker metals. Simply put, laser cutting is like a refined surgical procedure, while plasma cutting is more like a controlled explosion.

What can a 20-watt laser cut

Ah, the elegant powerhouse that is the 20-watt laser. While it may not be the mightiest tool in the shed, a 20-watt laser can still work wonders. It’s suitable for cutting thin materials like paper, cardboard, and thin fabrics. It’s also great for engraving and etching various surfaces. So, if you’re looking to add some intricate designs or personalization to your crafts, a 20-watt laser might be just what you need—without breaking the bank!

What can a 100-watt laser cut

Prepare to unleash the beast! A 100-watt laser is a force to be reckoned with. With this mighty machine, you can cut through thicker materials like wood, acrylic, and even some metals. It’s perfect for projects that require both power and precision, whether you’re carving elaborate designs or fabricating intricate parts. So, if you’re in need of some serious cutting power, a 100-watt laser will definitely make you the Jedi Knight of laser cutting.

How much does laser cut acrylic cost

Ah, the ever-popular acrylic material—the go-to choice for sleek and modern designs. The cost of laser cutting acrylic can vary depending on factors such as material thickness, design complexity, and the specific laser cutting service you choose. As of 2023, you can expect to pay around $2 to $4 per minute of laser cutting time, with additional charges for setup and any additional services you may require. Just remember, the end result of beautifully precise cuts in acrylic is priceless!